Cell Inspection

GPR Imaging Contractor Leads Search at Port of Jacksonville

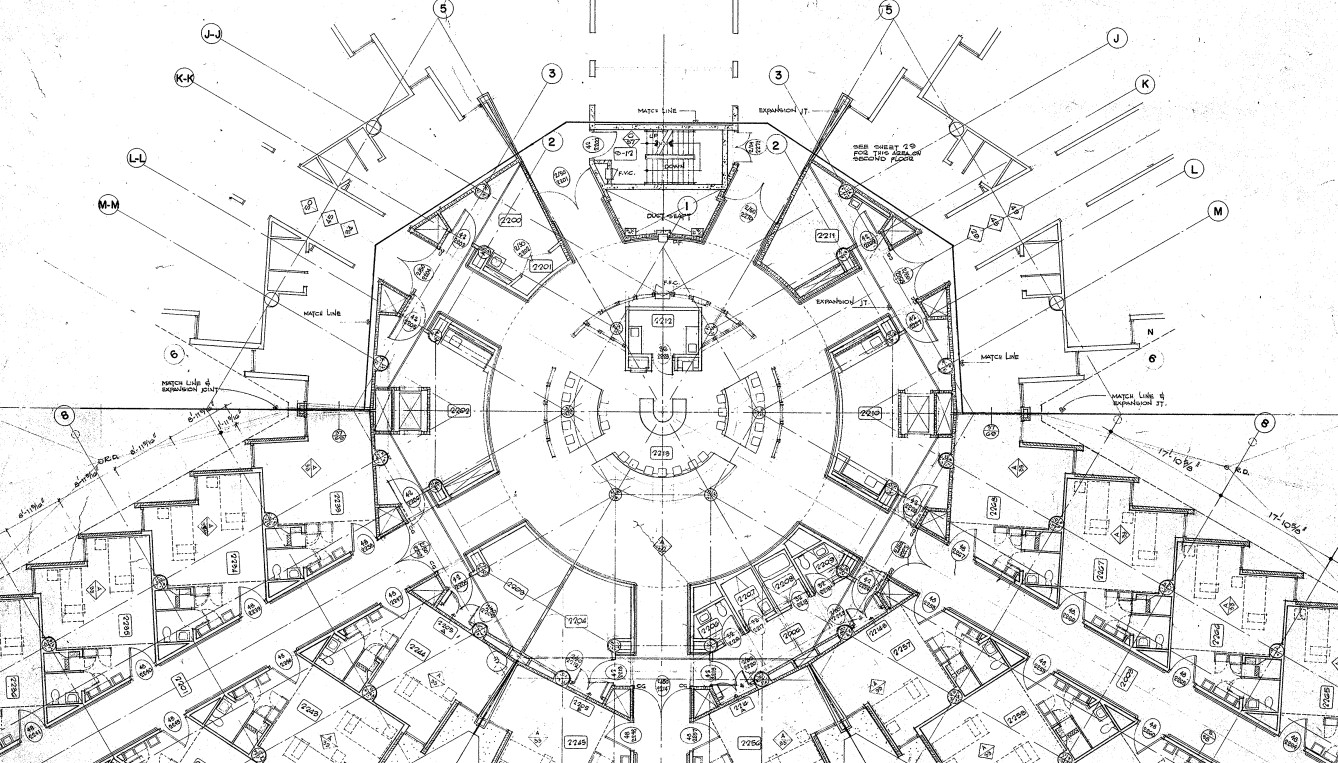

A CSDA member specializing in the field of Ground Penetrating Radar (GPR) imaging was recently contacted by a major petroleum company to inspect the 1-foot-thick outer ring of four large 45-foot-diameter reinforced concrete docking cells at the Port of Jacksonville, Florida. The structures were over 50 years old and in need of repair. While it was known the cells had undergone minor repairs and various strengthening work over the years, the condition and quantity of the reinforcement was unknown, along with their structural integrity.

The technician investigated the cells for the presence of steel reinforcing bars.

Adam Yunker, regional manager for CSDA member GPRS, Inc. in northern Florida, was tasked with using his imaging equipment on four cells that were built in the early to mid-1900s. The original design of the docking cells was sufficient to accommodate the size of ships at that time, but as larger ships began anchoring at these cells, the integrity of concrete structures needed to be redesigned.

Over the years, the docking cells had been reinforced with outer layers of sheet piling and concrete, but the client was unsure if rebar had been used in the most outer layer. The outer layer of sheet piling and concrete had begun to decay and was damaged in a few areas, so in order for the client to repair the cells, the GPR technician had to capture and evaluate data to help determine the condition of the concrete and steel rebar within them. The use of non-intrusive, non-destructive testing methods has many benefits, including reduced time, risk and cost.

Identifying the presence of rebar was critical to maintaining the integrity and safety of these concrete structures. By using state-of-the-art GPR mapping technology to measure the strength of reflection in rebar, the GPRS technician was able to identify the structural risks in the concrete and allow the client to begin remediation before any deterioration compromised the structure. In addition, the technical expertise in interpreting and mapping this data helped the client perform other maintenance work before other areas of deterioration became more extensive and costly to repair.

To gain access to the cells, Yunker needed to ride out on a boat with a crew of four men and use a ladder system to get to the top of each one. The GPR technician was issued with a life vest and all applicable personal protective equipment for working on and around the structures. A StructureScan Mini from CSDA member Geophysical Survey Systems, Inc. (GSSI), a unit that did not require cables or other equipment, was employed for the job. The handheld device was easy to transport on the boat and set up on the structures.

Data collected by the technician was analyzed and the results given to the customer.

The task of imaging the 1-foot-thick outer ring of the first cell began by setting up the GPR equipment at a start point and scanning to a depth of 18 to 20 inches. The technician scanned an approximate 1-2 foot area around the entire circumference perpendicular to the outer edge, then around the outer edge in a grid pattern. The process was then repeated for the other three cells, accounting for two hours of imaging work in total; each cell took approximately 20 minutes to scan. Typically, this type of imaging job can take longer to complete as many clients require the marking and color-coded identification of objects using spray paint. However, since the customer simply needed to confirm the presence of structural steel, no markings were required.

After collating and reviewing the data gathered by the GPR equipment, the technician was able to determine that two of the cells did not have any reinforcement, while the other two cells did contain rebar. Based on this information, engineers were able to determine the proper course of action to complete the necessary repairs.

“With the information we provided, the client was able to make the necessary repairs to the two cells and make the determination if additional reinforcement was needed on the other two. Knowing what was below the surface of the concrete gave the client the confidence and knowledge to make the best decision,” explained Yunker.

A growing number of companies are employing specialty contractors that utilize the latest technologies in GPR, concrete x-ray and electromagnetic induction to identify hidden objects and potential hazards. Experienced industry technicians like those from GPRS use these tools to provide immediate and accurate detection of subsurface elements, allowing construction managers, engineers, contractors, utility workers and homeowners to safely conduct their jobs in less time and at a lower cost. In addition, the identification of objects such as utility pipes, cabling and conduit can help sawing and drilling contractors to avoid damaging them during their work.

Company Profile

Ground Penetrating Radar Systems, Inc. (GPRS) was established in 2001 and has been a CSDA member for two years. The company is based in Toledo, Ohio with branch locations in every major city across the U.S. GPRS, Inc. currently has 85 trucks, over 100 technicians and offers the non-destructive testing services of ground penetrating radar and utility scanning.

Resources

Imaging Contractor:

GPRS, Inc.

Toledo, Ohio

Phone: 419-843-9804

Email: matthew.dragon@gp-radar.com

Website: www.gp-radar.com

Methods Used: GPR Imaging