Berth Replacement

New Wharf and Seawall Constructed Following Extensive Cutting Work

A specialty concrete sawing and drilling contractor was recently called to Port Manatee on the southeastern edge of Tampa Bay, Florida, to cut and remove a 600-foot-long, 44-foot-wide section of a 3-foot-thick concrete wharf and seawall. A new, more robust design was to be installed in front and over a portion of the old bulkhead, so the cutting work had to be clean and precise.

Orion Marine Group was contracted by the Manatee County Port Authority for the replacement of Berth 9 at Port Manatee, the closest U.S. deepwater seaport to the Panama Canal. The port generates more than $2.3 billion in annual economic impact for the local community, while supporting more than 24,000 jobs. Each of the port’s 10 berths are maintained at 40-foot design draft at mean low water and can accommodate large Panamax ships.

Slab saws were used to make 24-inch-deep cuts in the structure.

The preservation of the berthing area’s structural integrity and the protection of large-diameter fuel lines were critical to the job. Large breakers or hoe-rams were specifically prohibited for use on the existing 4.5-foot bulkhead cap area and around several areas where 8- and 10-inch-diameter fuel lines ran under the slab. Therefore, methods with low percussion and minimal debris were required. The general contractor enlisted the help of an experienced contractor that had the right tools for the job.

CSDA member Accu-Cut Concrete Services, Inc. of Clearwater, Florida, was contracted by Orion Marine Group to cut the entire slab into sections weighing roughly 12 tons, which would then be lifted out with a crane and trucked to a nearby crushing facility for recycling. The sawing and drilling contractor was also tasked with core drilling 74 holes 6 inches in diameter on a 2-degree angle through the existing bulkhead wall, which was approximately 4.5 feet thick with an embedded 0.625-inch-thick steel sheet pile. These holes were for new 3.5-inch-diameter tie rods, which would pass through and connect the new bulkhead to a new land side grade beam.

“The project was bid in 2015, but we were awarded the contract in January 2016 and sawing was to begin on the 3-foot-thick slab the following month,” explained John Robinson, owner of Accu-Cut. “Our plan was to saw the slab to 24 inches deep using our standard diesel slab saws, then cut the remaining 12 inches with our custom-fabricated Bobcat saw using 72- and 91-inch-diameter blades.”

Accu-Cut employed three large track-hoes equipped with hydraulic breakers for approximately half of the berth’s slab area while diamond saw cutting techniques were used on the other half, where the breakers could not be used. As the cutting team would be working on or near water, all personnel wore life jackets as part of their standard PPE.

The contractor completed 3,600 square feet of wire sawing.

Operators began creating the initial 24-inch-deep cuts in the berthing structure’s slab using the company’s diesel-powered slab saws from Diamond Products. Then the custom Bobcat saw was set up to cut the final 12 inches. However, this machine had only a 65-horsepower engine powering the blade. While this amount of power had worked fine for the contractor on jobs with narrow plunge cuts for bridge diaphragms [read “Bayway to Go” from our December 2013 issue], it was not powerful enough for continuous sawing at a depth of 3 feet. Robinson decided to upgrade to a Chevrolet 350-cubic inch, 290-horsepower V8 engine to power the blade. This upgrade, together with a tight time frame to put it all together, presented Accu-Cut with many new challenges like extra weight, sufficient cooling and power transmission from the engine to the blade shaft.

Once the Bobcat saw was ready and sawing commenced, the contractor found many areas of the slab with voids under it as deep as 6 to 8 inches. When the saw cut through these areas, the 24-ton sections created would drop causing the blade to jam. This would also cause belts to break or strip segments off the blade, so the order of cuts was planned very carefully to leave some areas with small amounts of uncut concrete to avoid these issues. In total, Accu-Cut completed over 4,000 linear feet of slab sawing with the Bobcat saw.

As sections of the slab were removed, a cut was made 4.5 feet from the water-side facia where the slab was 3 feet thick. This left an area that encapsulated the existing sheet piles and extended 11 feet downward on the water side. The remaining 4.5-foot-wide cap section had to be cut horizontally 18 inches lower, through the 4.5-foot cross section that contained the 0.625-inch-thick sheet pile. The sheet pile ran the entire length of the berth—640 feet.

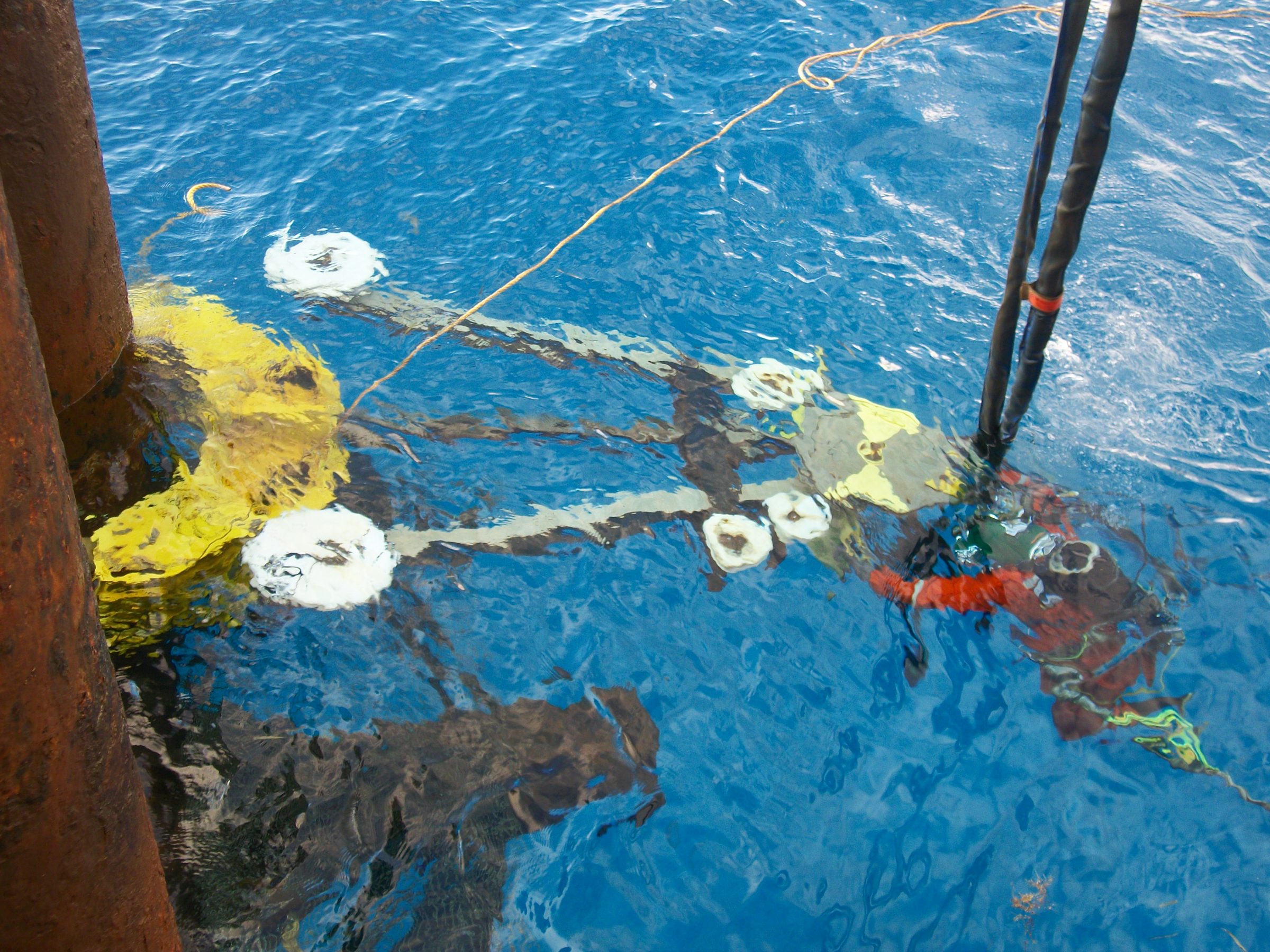

With all slab sawing work complete, operators began core drilling the 74 tie-back or tie-rod holes. These were 6-inch-diameter holes drilled through the existing seawall from the water side, with operators working from a small floating steel barge. The holes had to be 2 degrees from horizontal to allow the 3.5-inch-diameter tie-rods to align with the proper connection location on the grade beam. At the point where the bits penetrated the wall, thicknesses would vary from 2.5 to 4.5 feet and operators would drill through the 0.625-inch steel sheet pile in every hole. In some cases, the core bit had to cut through the interlocking joint in the steel sheet pile. Accu-Cut used Weka DK52 and DK42 480-volt core drill motors from Diamond Products fitted with custom-length core bits and running on custom rigs. When drilling near the salt water, operators had to take extra care and be sure all ground fault and Equipment Leakage Circuit Interrupters were in use and working properly.

Wire sawing techniques were used along the concrete seawall cap.

All that remained was the 4.5-foot-wide, 648-foot-long seawall cap, which was cut by wire saw. Accu-Cut had to set up horizontal cuts 18 inches lower to allow the new slab and cap to be constructed over it. The contractor utilized two modified Hydrostress SKB wire saws to cut 20-foot-long, 4.5-foot-wide sections. Wire sawing techniques were also used around several concrete vault boxes to separate them from the old slab. These vaults were enclosures that housed connections used by ships to access fuel from pipes under the slab. It was important that these vaults and the pipes going to them were not disturbed or damaged in any way. This resulted in 3,600 square feet of wire sawing work on the berthing structure.

Once the slab was removed, the terrain underneath was difficult for workers to traverse. The wet mud was, in places, deeper than the rubber boot worn by the workers. This was compounded by the stormy weather conditions associated with Florida summers, where almost daily afternoon thunderstorms are the norm. In addition, two hurricanes moved close to the Tampa Bay area in the summer of 2016. Although Accu-Cut suffered no damage, the contractor did lose time preparing for the hurricanes—moving and securing equipment.

Despite some challenges to overcome at the beginning the project, Accu-Cut successfully completed all specified cutting tasks and was been awarded extra work on this project.

“We have a long standing relationship with Orion Marine Group and the company was confident of our abilities to get this job done to everyone’s satisfaction. Where there have been some unique situations or uncommon specifications, we have worked with innovation and determination to come up with solutions,” concluded Robinson.

Work on the replacement of Berth 9 at Port Manatee began in February 2016 and Accu-Cut finished its portion of work around eight months later. All demolition has been completed and new concrete has been placed for the construction of the new structure. It is anticipated the new Berth 9 will be opened to vessels in summer 2017.

Company Profile

Accu-Cut Concrete Services, Inc. has been a CSDA member for 15 years and was established in 1990. The company is based in Clearwater, Florida, and services the southeastern U.S. and the Caribbean. Accu-Cut Concrete Services, Inc. has five trucks, 10 employees and offers the concrete cutting services of flat sawing, core drilling, wall sawing, wire sawing, hand sawing and grinding. Accu-Cut is a CSDA Certified Operator company.

Resources

General Contractor:

Orion Marine Construction

Sawing and Drilling Contractor:

Accu-Cut Concrete Services, Inc.

Clearwater, Florida

Phone: 727-787-4843

Email: accucut@tampabay.rr.com

Methods Used: Core Drilling, Wire Sawing, Flat Sawing