CSDA Contractor Works Underwater to Prevent Future Catastrophe

On the Hudson River waterfront in Jersey City, New Jersey, a 100-foot wide by roughly 1,700-foot-long canal runs adjacent to the tracks of NJ TRANSIT’s Hoboken Yards. The canal, known as the Long Slip, was previously used for shipping traffic, but had been inactive for over 40 years. When Superstorm Sandy made landfall in New Jersey in 2012, it caused the banks of the Long Slip to overflow, causing enormous flood damage to the Hoboken Yards, halting NJ TRANSIT services for weeks during the repair efforts. The Long Slip project, initiated in 2019 with a hefty $40-million budget, plans to eliminate the Long Slip as an intermediary for the flood water which would expand NJ TRANSIT’s capacity to operate during and recuperate from these intense storm events.

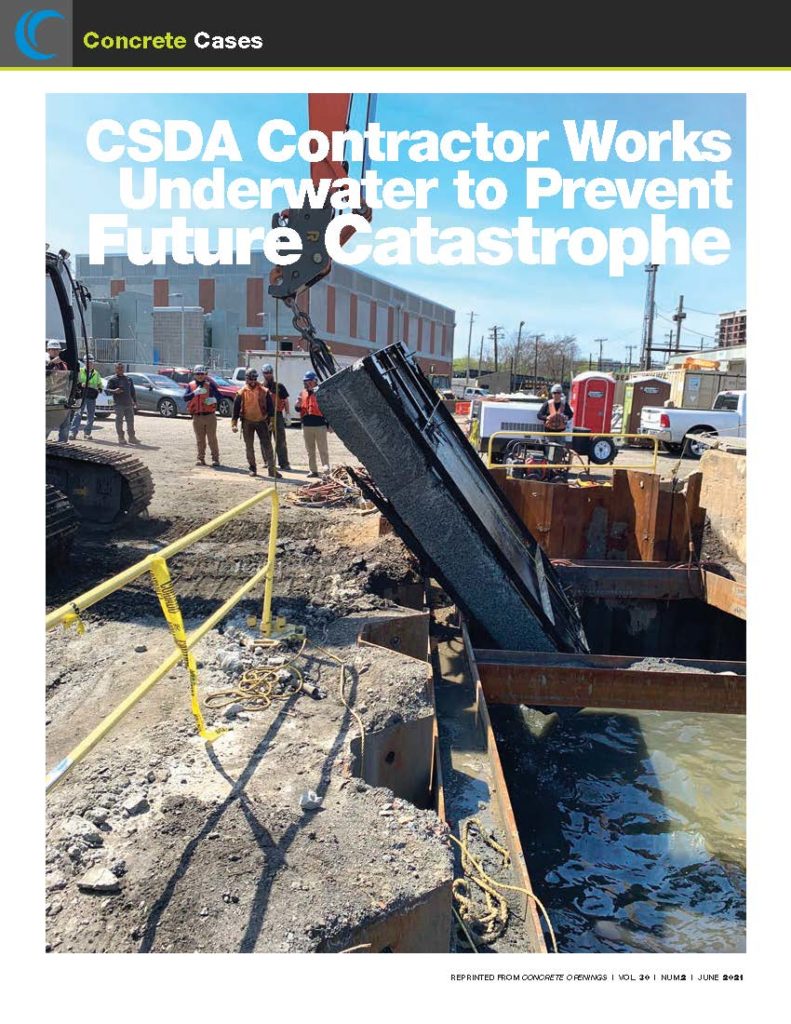

NJ TRANSIT awarded general contractor Walsh Construction Co. with the $40 million contract for the first phase of the renovation of the Long Slip, which consists of work both above and below the water. Fortunately for Walsh Construction, CSDA contractor Walker Cutting Services, a division of Walker Diving Underwater Construction, is headquartered just a short drive away in Hammonton, New Jersey and had the knowledge and manpower for the underwater element of this job. The task was removal of an 11.5-foot high by 7-foot wide slab of concrete that ranged in depth from 18 inches to 32 inches. Removal was necessary to create a new opening in the outfall structure in the canal, 10 feet below the surface of the water.

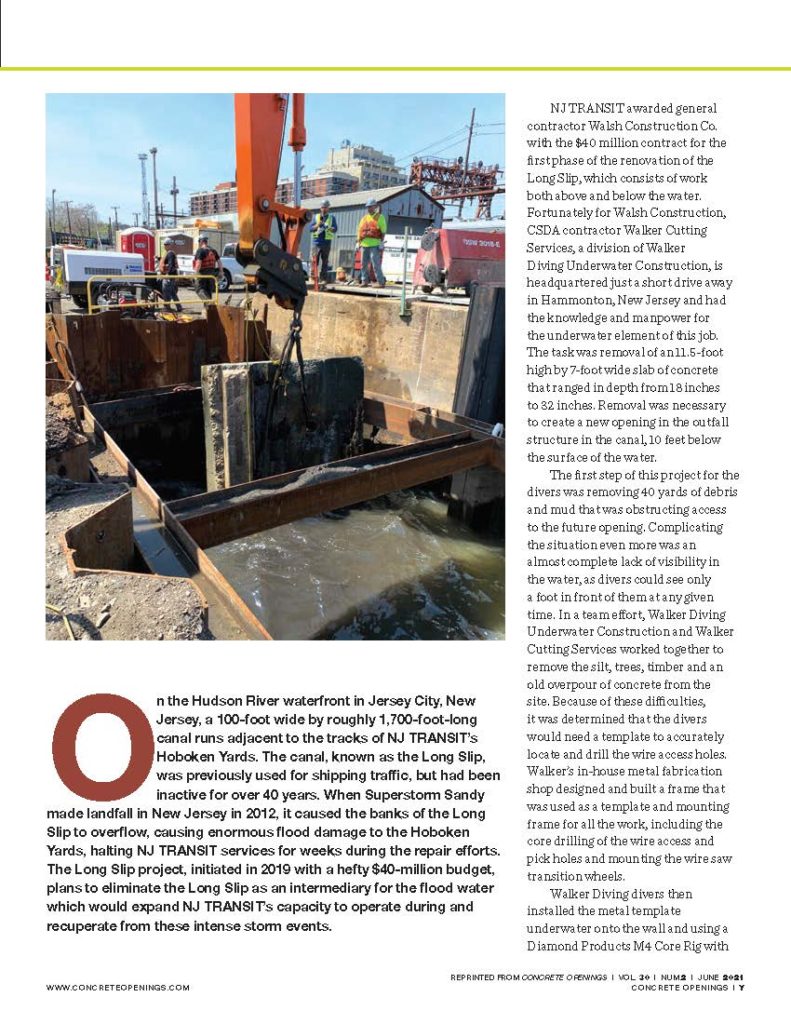

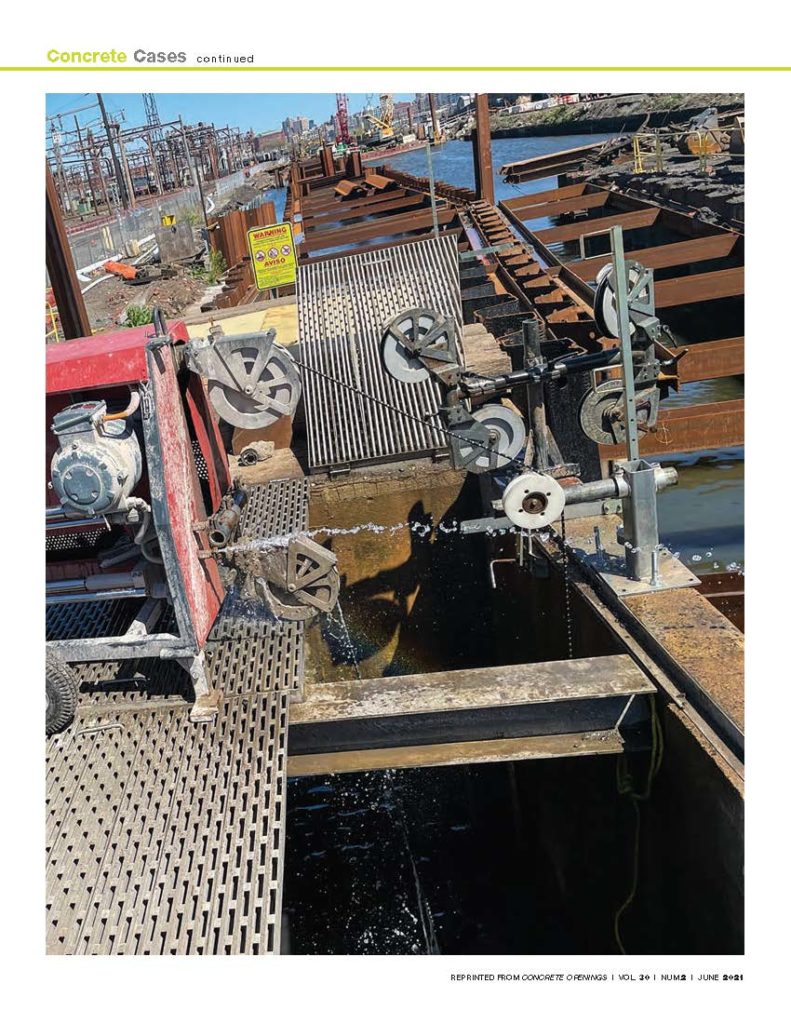

The first step of this project for the divers was removing 40 yards of debris and mud that was obstructing access to the future opening. Complicating the situation even more was an almost complete lack of visibility in the water, as divers could see only a foot in front of them at any given time. In a team effort, Walker Diving Underwater Construction and Walker Cutting Services worked together to remove the silt, trees, timber and an old overpour of concrete from the site. Because of these difficulties, it was determined that the divers would need a template to accurately locate and drill the wire access holes. Walker’s in-house metal fabrication shop designed and built a frame that was used as a template and mounting frame for all the work, including the core drilling of the wire access and pick holes and mounting the wire saw transition wheels.

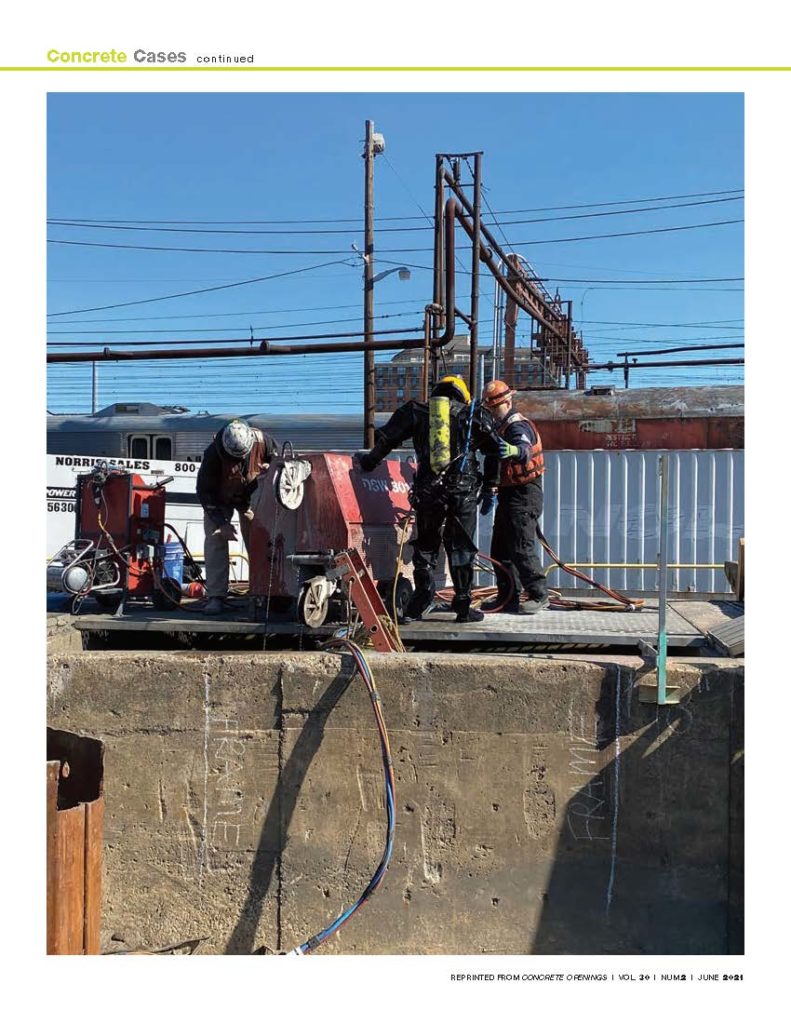

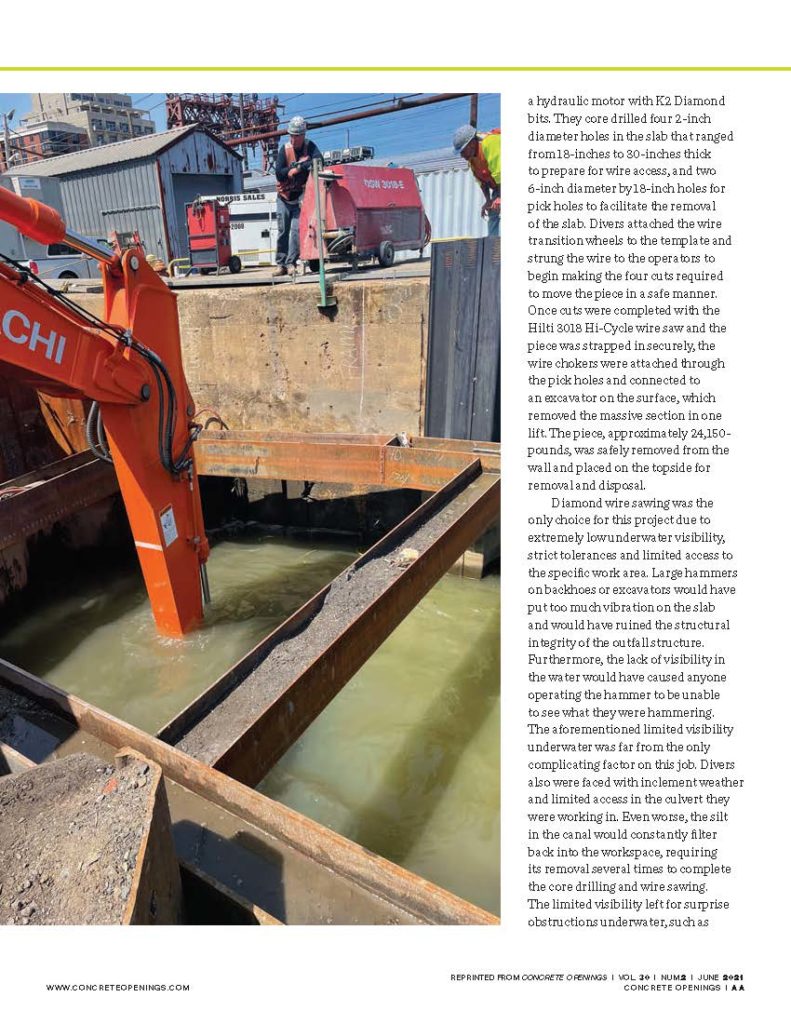

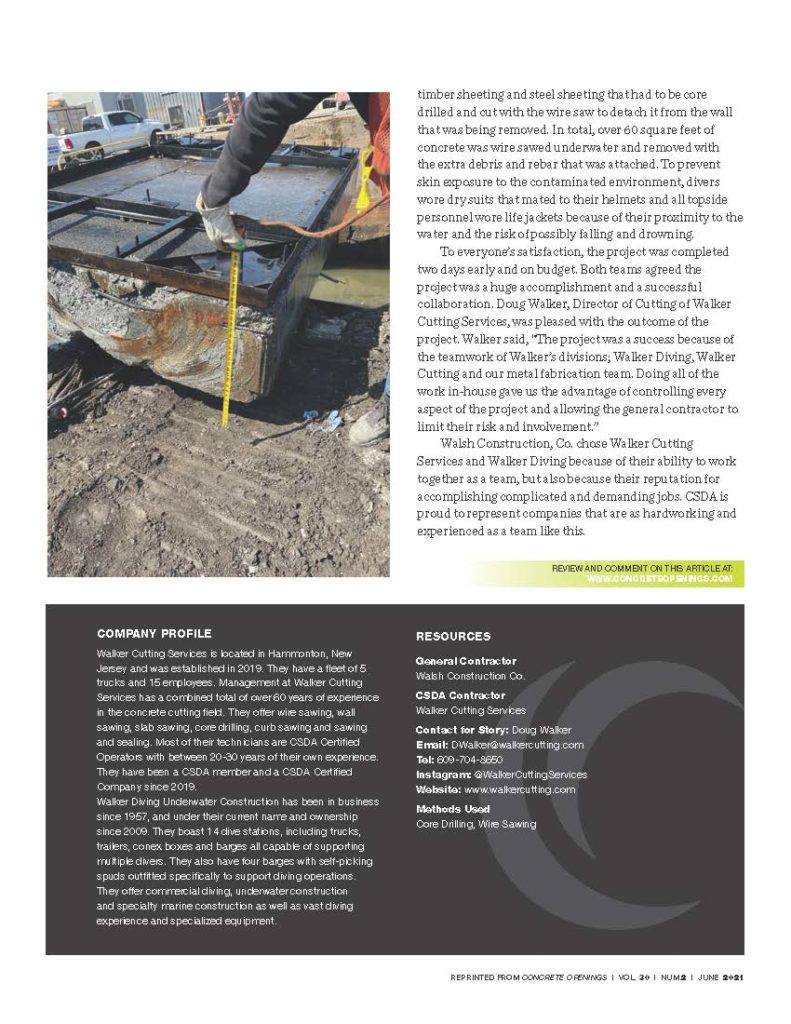

Walker Diving divers then installed the metal template underwater onto the wall and using a Diamond Products M4 Core Rig with a hydraulic motor with K2 Diamond bits. They core drilled four 2-inch diameter holes in the slab that ranged from 18-inches to 30-inches thick to prepare for wire access, and two 6-inch diameter by 18-inch holes for pick holes to facilitate the removal of the slab. Divers attached the wire transition wheels to the template and strung the wire to the operators to begin making the four cuts required to move the piece in a safe manner. Once cuts were completed with the Hilti 3018 Hi-Cycle wire saw and the piece was strapped in securely, the wire chokers were attached through the pick holes and connected to an excavator on the surface, which removed the massive section in one lift. The piece, approximately 24,150-pounds, was safely removed from the wall and placed on the topside for removal and disposal.

Diamond wire sawing was the only choice for this project due to extremely low underwater visibility, strict tolerances and limited access to the specific work area. Large hammers on backhoes or excavators would have put too much vibration on the slab and would have ruined the structural integrity of the outfall structure. Furthermore, the lack of visibility in the water would have caused anyone operating the hammer to be unable to see what they were hammering. The aforementioned limited visibility underwater was far from the only complicating factor on this job. Divers also were faced with inclement weather and limited access in the culvert they were working in. Even worse, the silt in the canal would constantly filter back into the workspace, requiring its removal several times to complete the core drilling and wire sawing. The limited visibility left for surprise obstructions underwater, such as timber sheeting and steel sheeting that had to be core drilled and cut with the wire saw to detach it from the wall that was being removed. In total, over 60 square feet of concrete was wire sawed underwater and removed with the extra debris and rebar that was attached. To prevent skin exposure to the contaminated environment, divers wore dry suits that mated to their helmets and all topside personnel wore life jackets because of their proximity to the water and the risk of possibly falling and drowning.

To everyone’s satisfaction, the project was completed two days early and on budget. Both teams agreed the project was a huge accomplishment and a successful collaboration. Doug Walker, Director of Cutting of Walker Cutting Services, was pleased with the outcome of the project. Walker said, “The project was a success because of the teamwork of Walker’s divisions; Walker Diving, Walker Cutting and our metal fabrication team. Doing all of the work in-house gave us the advantage of controlling every aspect of the project and allowing the general contractor to limit their risk and involvement.”

Walsh Construction, Co. chose Walker Cutting Services and Walker Diving because of their ability to work together as a team, but also because their reputation for accomplishing complicated and demanding jobs. CSDA is proud to represent companies that are as hardworking and experienced as a team like this.

COMPANY PROFILE

Walker Cutting Services is located in Hammonton, New Jersey and was established in 2019. They have a fleet of 5 trucks and 15 employees. Management at Walker Cutting Services has a combined total of over 60 years of experience in the concrete cutting field. They offer wire sawing, wall sawing, slab sawing, core drilling, curb sawing and sawing and sealing. Most of their technicians are CSDA Certified Operators with between 20-30 years of their own experience. They have been a CSDA member and a CSDA Certified Company since 2019.

Walker Diving Underwater Construction has been in business since 1957, and under their current name and ownership since 2009. They boast 14 dive stations, including trucks, trailers, conex boxes and barges all capable of supporting multiple divers. They also have four barges with self-picking spuds outfitted specifically to support diving operations. They offer commercial diving, underwater construction and specialty marine construction as well as vast diving experience and specialized equipment.

RESOURCES

General Contractor: Walsh Construction Co.

CSDA Contractor: Walker Cutting Services

Contact for Story: Doug Walker Email: DWalker@walkercutting.com Tel: 609-704-8650

Instagram: @WalkerCuttingServices Website: www.walkercutting.com

Methods Used: Core Drilling, Wire Sawing