Concrete Polishing Restores Luster to a Vintage Motorcycle Museum

For a concrete refurbishing contractor, it is a good thing to have grinders and related polishing equipment at work on a job site, but when that equipment is down for repairs or needed at another location, what are the options?

For PaintSmiths of Missouri, the answer was Sunbelt Flooring Solutions, a nationwide company that rents a full line of concrete grinding and polishing machines, tooling and HEPA dust collectors. PaintSmiths turned to Sunbelt for the equipment required to tackle a concrete polishing project at the Moto Museum in St. Louis, Missouri.

The Moto Museum is a 16,000-square foot facility housing a collection of vintage motorcycles dating back to the turn of the twentieth century, including some of the rarest bikes still in existence. The museum, which grew out of the private collection of owner and founder Steve Smith, has six galleries featuring unique motorcycles from around the world. Two of the museum’s galleries are leased for special events such as conferences, retreats, weddings, birthdays and family reunions.

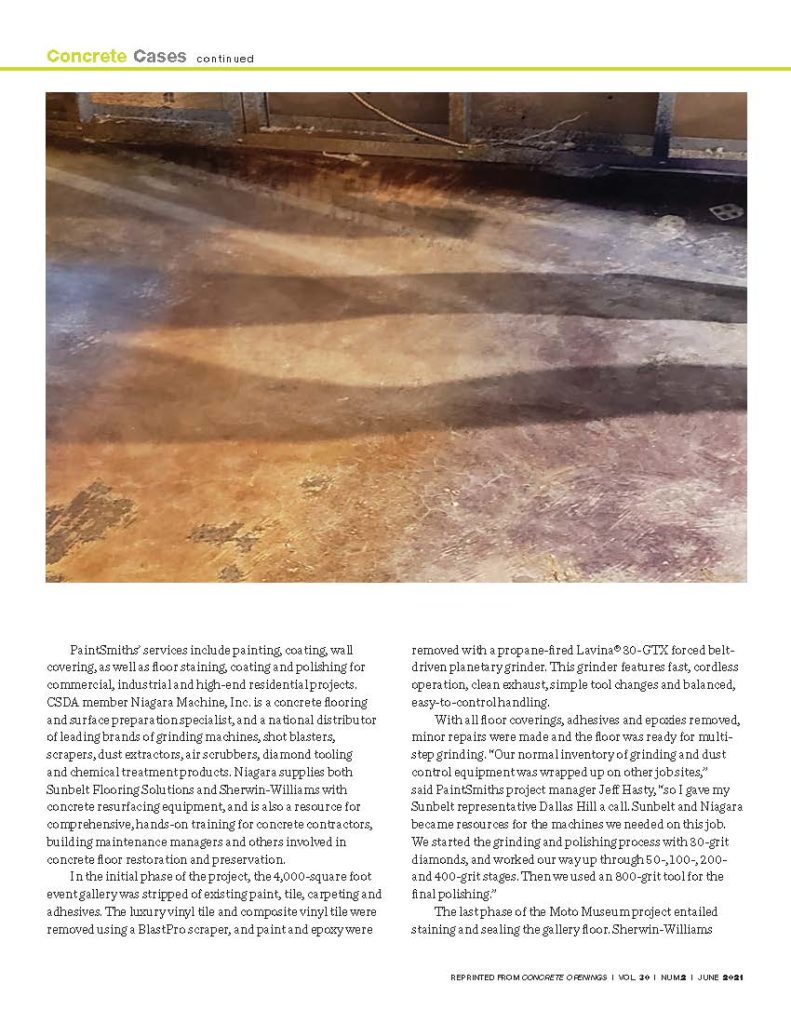

A recent renovation project at Moto Museum entailed a plan to repair and polish a worn concrete floor in an event gallery. The floor had a variety of coverings—including paint, epoxy, carpeting, luxury vinyl tile and vinyl composite tile—and was stained, scuffed and worn from decades of heavy traffic.

The Moto Museum floor refurbishing project was a joint venture involving PaintSmiths of St. Louis, Inc., Sunbelt Flooring Solutions, Niagara Machine, Inc. and Sherwin–Williams H&C division, which supplied the concrete treatment chemicals used for the project.

PaintSmiths’ services include painting, coating, wall covering, as well as floor staining, coating and polishing for commercial, industrial and high-end residential projects. CSDA member Niagara Machine, Inc. is a concrete flooring and surface preparation specialist, and a national distributor of leading brands of grinding machines, shot blasters, scrapers, dust extractors, air scrubbers, diamond tooling and chemical treatment products. Niagara supplies both Sunbelt Flooring Solutions and Sherwin-Williams with concrete resurfacing equipment, and is also a resource for comprehensive, hands-on training for concrete contractors, building maintenance managers and others involved in concrete floor restoration and preservation.

In the initial phase of the project, the 4,000-square foot event gallery was stripped of existing paint, tile, carpeting and adhesives. The luxury vinyl tile and composite vinyl tile were removed using a BlastPro scraper, and paint and epoxy were removed with a propane-fired Lavina® 30-GTX forced belt-driven planetary grinder. This grinder features fast, cordless operation, clean exhaust, simple tool changes and balanced, easy-to-control handling.

With all floor coverings, adhesives and epoxies removed, minor repairs were made and the floor was ready for multi-step grinding. “Our normal inventory of grinding and dust control equipment was wrapped up on other job sites,” said PaintSmiths project manager Jeff Hasty, “so I gave my Sunbelt representative Dallas Hill a call. Sunbelt and Niagara became resources for the machines we needed on this job. We started the grinding and polishing process with 30-grit diamonds, and worked our way up through 50-, 100-, 200- and 400-grit stages. Then we used an 800-grit tool for the final polishing.”

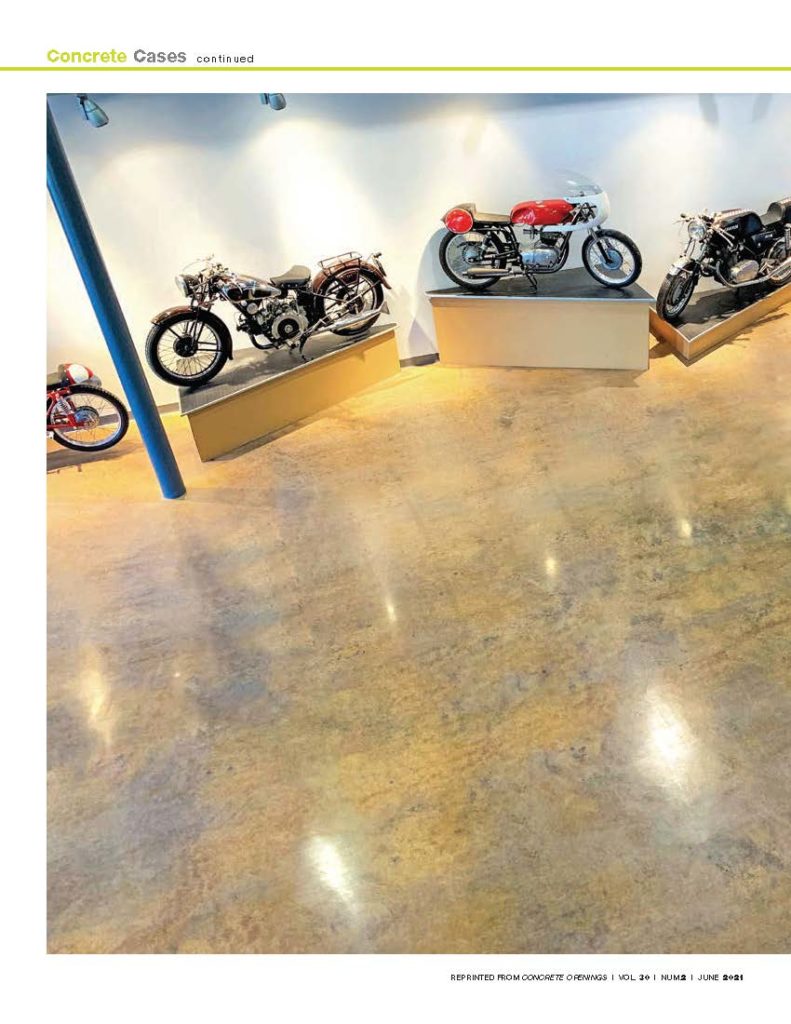

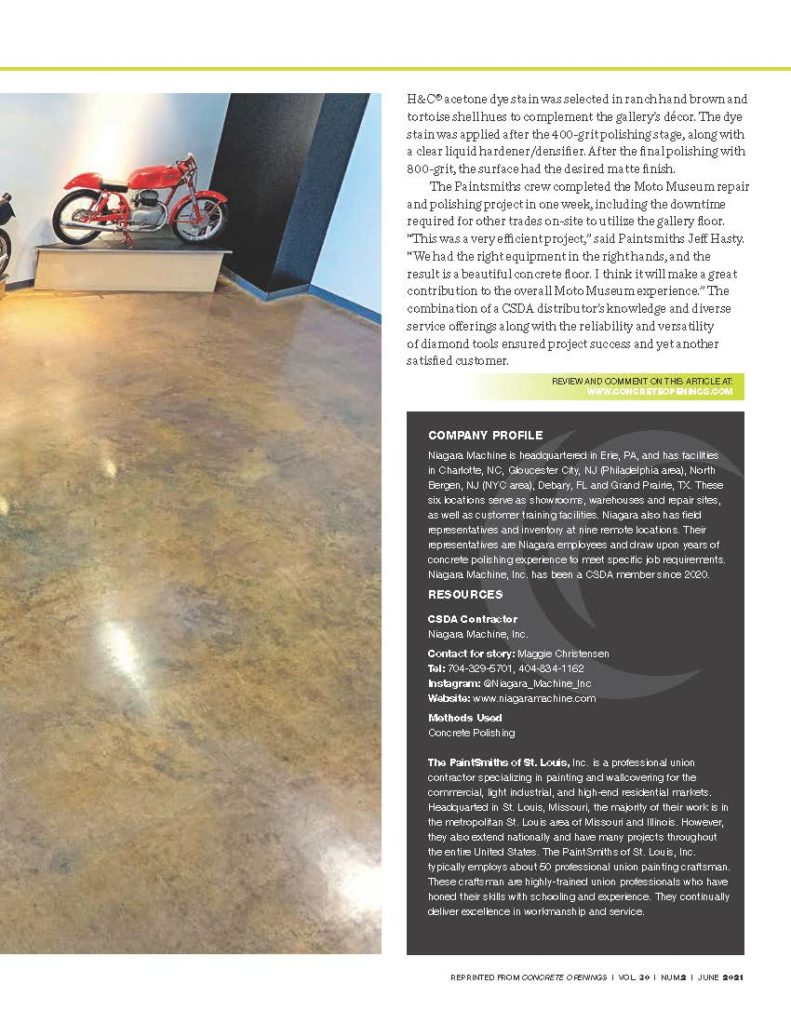

The last phase of the Moto Museum project entailed staining and sealing the gallery floor. Sherwin-Williams H&C® acetone dye stain was selected in ranch hand brown and tortoise shell hues to complement the gallery’s décor. The dye stain was applied after the 400-grit polishing stage, along with a clear liquid hardener/densifier. After the final polishing with The Paintsmiths crew completed the Moto Museum repair and polishing project in one week, including the downtime required for other trades on-site to utilize the gallery floor.

“This was a very efficient project,” said Paintsmiths Jeff Hasty. “We had the right equipment in the right hands, and the result is a beautiful concrete floor. I think it will make a great contribution to the overall Moto Museum experience.” The combination of a CSDA distributor’s knowledge and diverse service offerings along with the reliability and versatility of diamond tools ensured project success and yet another satisfied customer.

COMPANY PROFILE

Niagara Machine is headquartered in Erie, PA, and has facilities in Charlotte, NC, Gloucester City, NJ (Philadelphia area), North Bergen, NJ (NYC area), Debary, FL and Grand Prairie, TX. These six locations serve as showrooms, warehouses and repair sites, as well as customer training facilities. Niagara also has field representatives and inventory at nine remote locations. Their representatives are Niagara employees and draw upon years of concrete polishing experience to meet specific job requirements. Niagara Machine, Inc. has been a CSDA member since 2020.

RESOURCES

CSDA Contractor: Niagara Machine, Inc.

Contact for story: Maggie Christensen

Tel: 704-329-5701, 404-834-1162

Instagram: @Niagara_Machine_Inc

Website: www.niagaramachine.com

Methods Used: Concrete Polishing

The PaintSmiths of St. Louis, Inc. is a professional union contractor specializing in painting and wallcovering for the commercial, light industrial, and high-end residential markets. Headquarted in St. Louis, Missouri, the majority of their work is in the metropolitan St. Louis area of Missouri and Illinois. However, they also extend nationally and have many projects throughout the entire United States. The PaintSmiths of St. Louis, Inc. typically employs about 50 professional union painting craftsman. These craftsman are highly-trained union professionals who have honed their skills with schooling and experience. They continually deliver excellence in workmanship and service.