Historic Smokestack Removed with Expert Precision

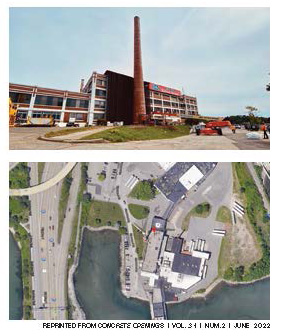

For nearly 70 years, the Burnham & Morrill Baked Beans factory brick smokestack was a staple of the Casco Bay skyline in Portland, Maine. Built in 1956 and visible from the Casco Bay Bridge, the smokestack that released sweet, molasses-scented steam for decades had seriously deteriorated after years of exposure to the salty sea air and nearly 20 years of non-use. With the brick structure becoming a potential hazard to the employees of the still-active factory, as well as the community, B&M decided to remove the iconic, yet deteriorated, structure.

The B&M factory and smokestack is surrounded by the ocean on three sides, complicating this procedure. Traditional demolition that would involve tipping the smokestack over was not an option because of the risk of bricks falling into the water or crashing through windows of the active factory. CSDA contractor Interstate Sawing and Demolition was contracted by General Contractor Industrial Access, to help solve this issue. Interstate, no stranger to robotic demolition, knew that the use of robots to take down the structure carefully and precisely was the best and safest way to complete the project. So, with the help of their Brokk 200 and 170 robots and a crane, Interstate crews began the grueling process of taking the smokestack down – brick by brick.

Interstate operators quickly realized that the brick was rotted out, making the smokestack extremely unstable. To support the demolition process, a temporary steel structure was installed to avoid unwanted tipping or crumbling. The reinforcement frame was installed to prevent premature failure of the structure as the bricks fell to the bottom of the opening of the smokestack during demolition. Interstate’s crew used a Hilti DSW 3018-E wire saw to saw the openings required to install the steel reinforcement frame. This partial steel reinforcement frame had an inner opening of approximately 8’ x 4’ and was installed around the existing smaller opening to the smokestack. Industrial Access operators completed the installation of the frame by welding 1/4” steel at the top of intel and along the vertical columns.

Once the support frame was installed, Interstate crews used a Brokk 200 and 170 with crusher and breaker attachments to begin the demolition. With two enormous cranes, one supporting the robot and the other supporting

the operators, Interstate crews were flown up 150’ into the air two at a time to begin the enormous undertaking. At the peak of the smokestack, one operator ran the robot, while the other operator in the lift was communicating with the crane operator from a two-person crane basket, until they had demolished enough of the smokestack to safely work from the boom lift. The 150’ smokestack was dismantled from top to bottom, scraping the cut and broken brick into the smokestack opening, and at points where the structure was very weak, only one brick could be removed at a time. Each night following the demolition, the debris was cleaned out using a backhoe through the 8’ x 4’ opening at bottom of smokestack. The Interstate crews moved at an impressive pace, removing an average of 25’ of the smokestack per day, completing the job without incident in just 6 days.

The B&M factory remained and still remains an active building, with people working inside near the smokestack during the entire removal process. Interstate crews had to be sure that no bricks or debris landed on the roof or broke any windows. They were happy to say that absolutely no damage was done to the building during the demolition, and the job was completed on time. Interstate, Industrial Access and the B&M factory owners were all very satisfied with how this job was completed. Sam Long, an Interstate operator onsite, said about this job, “This smokestack removal was both thrilling and nerve-racking. Each movement of the robot, crane and man basket had to be made strategically. We came in with a plan and safely removed the structure in less than a week without any interruptions!”

Interested readers can visit interstatesawing.com or youtube.com/interstatesawing to see a fascinating video detailing the process from the beginning to end, helping to understand just how perilous a job this could have been without an experienced and professional crew. CSDA members like Interstate demonstrate an unprecedented commitment to technology and efficiency, and their expert crews always bring us incredible stories to read and watch.

COMPANY PROFILE

Interstate Sawing & Demolition has been a leader in concrete cutting, confined space robotic demo, confined space lifting solutions, electric interior excavating, grinding and scanning since it was founded in 1996. Their vast knowledge of concrete renovation and removal, innovative ideas, and continuing commitment to excellence has helped their customers save time and money on their projects. Owner Duke Long is a working owner who has over 37+ years of on-the-job experience. Interstate Sawing & Demolition has 42 employees and a fully enclosed fleet of 25 service trucks, all of which are self-contained and mobile-ready. Interstate Sawing & Demolition specializes in robotic demolition, electric interior excavation, curb cutting, wire sawing, concrete grinding, hydraulic splitting, concrete removal, confined space lifting and GPR scanning. They have been a CSDA member since 1999.

RESOURCES

General Contractor

Industrial Access

CSDA Contractor

Interstate Sawing & Demolition

Contact for Story: Haley Long

Email: Haley@InterstateSawing.com

Tel: 262-334-7522

Website: Interstatesawing.com

Methods Used

Selective Demolition, Wire Sawing