New Life Brought to High School Commons Area

Maine West High School (MWHS) is situated in Des Plaines, Illinois, a suburb of Chicago, located just north of O’Hare International Airport. Named after the scenic Des Plaines River that runs south through the city from Wisconsin, Des Plaines is a cozy town with a population of about 60,000 and offers residents a mix of the suburban and urban feel, boasting a wide array of parks and outdoor activities, complemented by a variety of coffee shops, restaurants and nightlife selections.

Maine Township High Schools have embarked on a thorough revamp of all three high schools in their district: Maine East High School, Maine South High School and Maine West High School, with a whopping $240.7 million budget for the proposed upgrades. As part of their long-term improvement plan, Maine West High School hired Pepper Construction to renovate The Main West student union and dining area. To create a more open and inviting space, Pepper was tasked with removing the existing ceiling and floor to create a two-story atrium for the cafeteria. The layout of the school is an “X” formation, with the dining area and student union in an “O” shape at the very center of the four diagonal corridors. With these upgrades, the two-story area would have large open ceilings with natural light and a comfortable flow from floor-to-floor. However, time was of the essence because this project began over the summer and needed to be completed before school reassembled in the fall.

For safety reasons, the floor of the commons was scanned using Ground Penetrating Radar (GPR) in advance to make sure there were no utilities. Hard Rock Concrete Cutters scanned 13,000’ of flooring using a GSSI SIR 4000 with a 1600 MHz antenna before deciding to proceed with the cutting. Concrete cutting was specified because breaking the floor with something like jackhammers would have created an enormous amount of dust and debris. The falling pieces would have also created a safety hazard and would most likely have damaged the existing floor below, and vibration was a concern due to the suspended slab.

The demolition contractor onsite, Break Thru Demolition, hired CSDA member Hard Rock Concrete Cutters to cut and remove the existing 5” thick concrete floor and 18” thick concrete beams. The atrium is a 360° circle, so removing half of the floor required Hard Rock to cut a perfect half circle. This was going to be no small feat using a Core Cut CC3701 electric saw fitted with a 42” diamond blade with no overcuts. After the floor was scanned and the 180° semicircle was marked, operators then mapped out a 3’ x 3’ grid for extraction of the slabs.

Traditionally, Hard Rock would have had to drill 6” holes every 3’ around the perimeter to relieve pressure from the blade. However, Hard Rock operator Eric Chorowicki was able to make a radius cut without this step. The floor was shored up tightly from below with scaffolding and a catch deck, as well as with three steel I-Beams within the opening to support the second story while operators cut. Hard Rock cut the radius of the semicircle up to 18’’ through the concrete beams and joist. Straight line cuts and cuts through I-beams were left until the end of each section to keep the floor supported while working on the slab.

Hard Rock worked in three sections between the three I-beams; The opening was cut into 3’ x 3’ pieces working away from the radius cut so that the saw was always on stable flooring. As pieces were cut free, Break Thru removed pieces with the skid steer to avoid overloading shoring. Once a section was removed, Hard Rock cut the concrete encased I-beam into pieces to be removed by Break Thru. Lastly, they cut a straight line cut to finish the opening. Aside from the 180’ perimeter cut; Hard Rock operators performed 4,580’ of linear sawing and the entirety of the 13,000 square feet of floor removal.

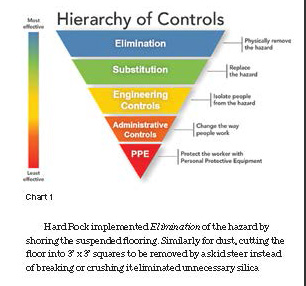

Hard Rock had a few safety concerns at the start of the job. Cutting on a suspended slab risked damage to surrounding structures as well as the possibility of debris falling on operators, not to mention the possibility of utilities that cannot be cut inside the slab. The inevitable dust while breaking the floor into pieces to be removed also posed a concern. Hard Rock fixed each issue by following The Hierarchy of Safety Controls (Chart 1).

dust in the air. The last major concern was the possibility of utilities running throughout the floor to be cut, which was solved by doing a preliminary scan of the floors. These techniques eliminated a lot of dust, noise and vibration safety hazards. By following the hierarchy of safety, Hard Rock was able to eliminate all specialized PPE but respirators.

The job began June 9, 2021, and was completed less than a month later on July 3, 2021, with plenty of time for additional renovations to be completed before students arrived for their first day of school in August. All contractors involved with the job were satisfied with the quality and length of the project. Roger Lisy, President of Break Thru Enterprises, Inc., said about this project, “It was a fine job by all, the school is absolutely blown away by the work!” Hard Rock Concrete Cutters say, “Building a ‘Safety First’ culture is the most important thing we do every day. Safety is First, Last and Always.” CSDA members like Hard Rock demonstrate just how important it is to prioritize the safety of everyone involved on the jobsite, especially in high-risk and complex settings.

COMPANY PROFILE

With more than 35 years of experience, Hard Rock Concrete Cutters has steadily grown into one of the most trusted names in Midwest construction because they have the experience and systems in place to address complicated situations in real time. Hard Rock has 78 employees and a fleet of 39 trucks. Their Field Superintendents, Safety Directors and Project Managers, as well as highly trained field personnel, all work together with their logistics team to keep the job on track. Whether they’re coring in tight spaces or salvaging historic architectural façades, they can be trusted to do the job exactly the way it is supposed to be done – safely, professionally, on time, and on budget. They have been a CSDA member since 1989.

RESOURCES

General Contractor

Pepper Construction, Break Thru Enterprises, Inc.

CSDA Contractor

Hard Rock Concrete Cutters

Contact for Story: Ted Stanaszek

Email: ted@hrccinc.com

Tel: 312-607-5853

Website: www.hardrockconcretecutters.com

Methods Used

Slab Sawing, GPR Scanning, Selective Demolition