Reinforcing Heights: Spanish Contractor Defies the Odds with Hydrodemolition for Cement Plant Silo

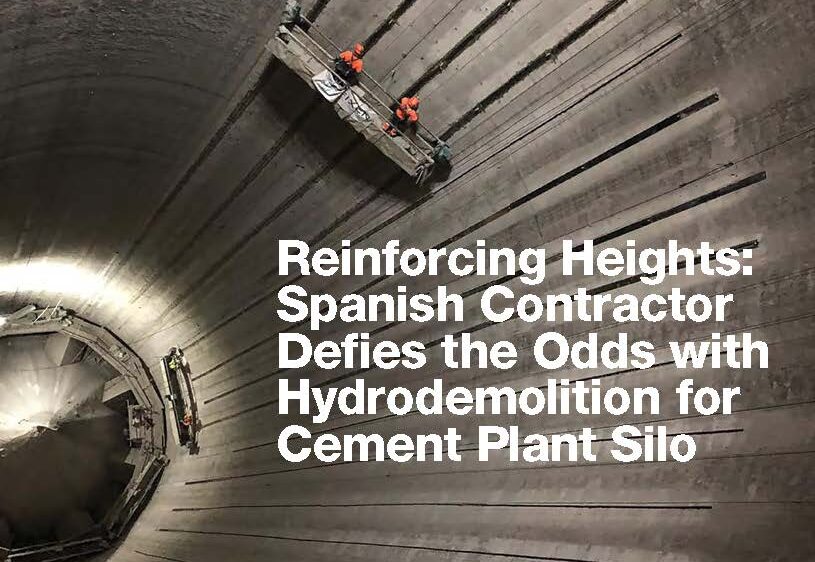

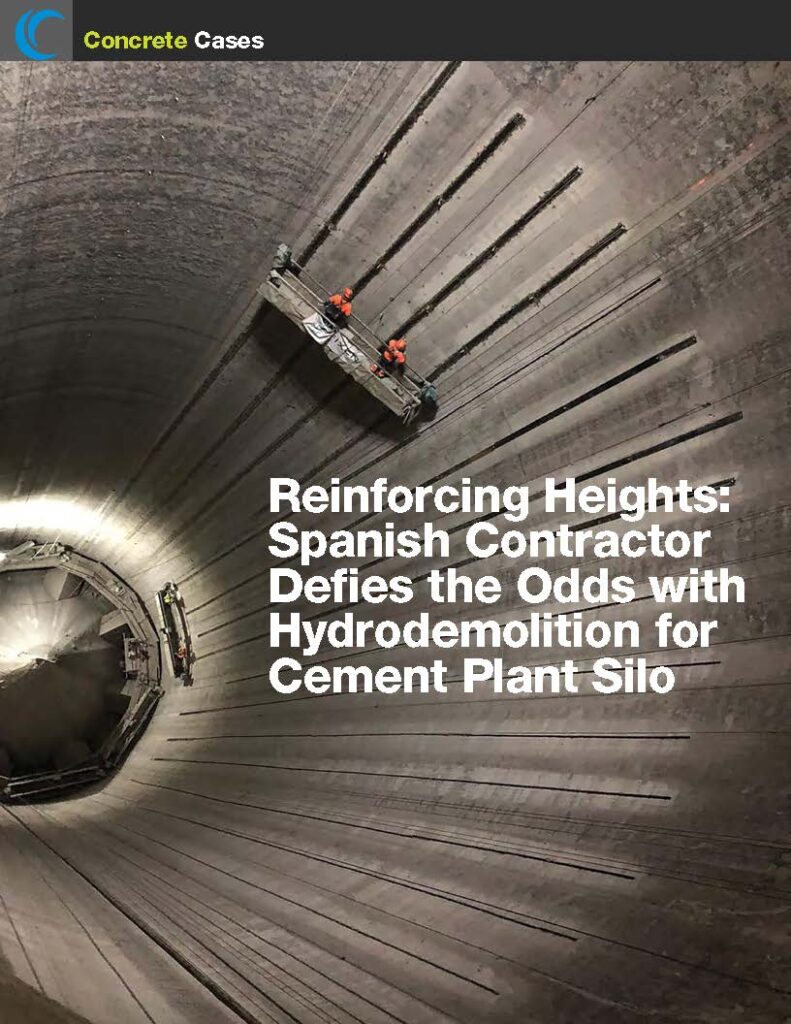

During an annual maintenance shutdown, a cement plant in the village of La Robla, Spain, needed an effective way to repair a 100m tall by 16m diameter concrete silo used to store raw materials. Similar to many silos built in the 20th century, the walls of the concrete vessel were held together with rebar on the outer and inner layers of concrete, but nothing was there to connect the two. With age, it resulted in deteriorating and falling concrete.

In 2019, the cement plant hired a company specializing in concrete and structure repair to fix the silo. The hired crew used hand lances to remove the deteriorating concrete and scaled the silo with a scaffolding system to reach the higher areas. Unfortunately, the crew was only able to repair the lower portion of the silo with the limited time they had, which put the remainder of the repair on hold.

When the project resumed two years later, Jose Rodriguez was hired to complete the repair. Rodriguez had been involved in the initial stage of repair and had since started another company, Fixen Structural Services, with a focus on structural reinforcements and repair. Fixen’s winning bid proposed using CSDA member Aquajet’s Ergo Hydrodemolition robot to complete the challenging repair on budget and ahead of schedule.

Rodriguez was introduced to Aquajet’s Ergo equipment in 2016, when he attended World of Concrete in Las Vegas. He was astonished by its versatility and ability to successfully operate in confined spaces. From his initial introduction to the Ergo, Rodriguez knew this piece of equipment would greatly benefit Fixen and its customers. Since the company invested in the Ergo in late 2020, the Fixen team has been thrilled with its quality, speed and accurate results. The equipment has proven to be a great replacement to hand lancing, with its power and precision to complete repairs with limited workspace. All in all, it has shown to be a more convenient, safe and cost-effective method.

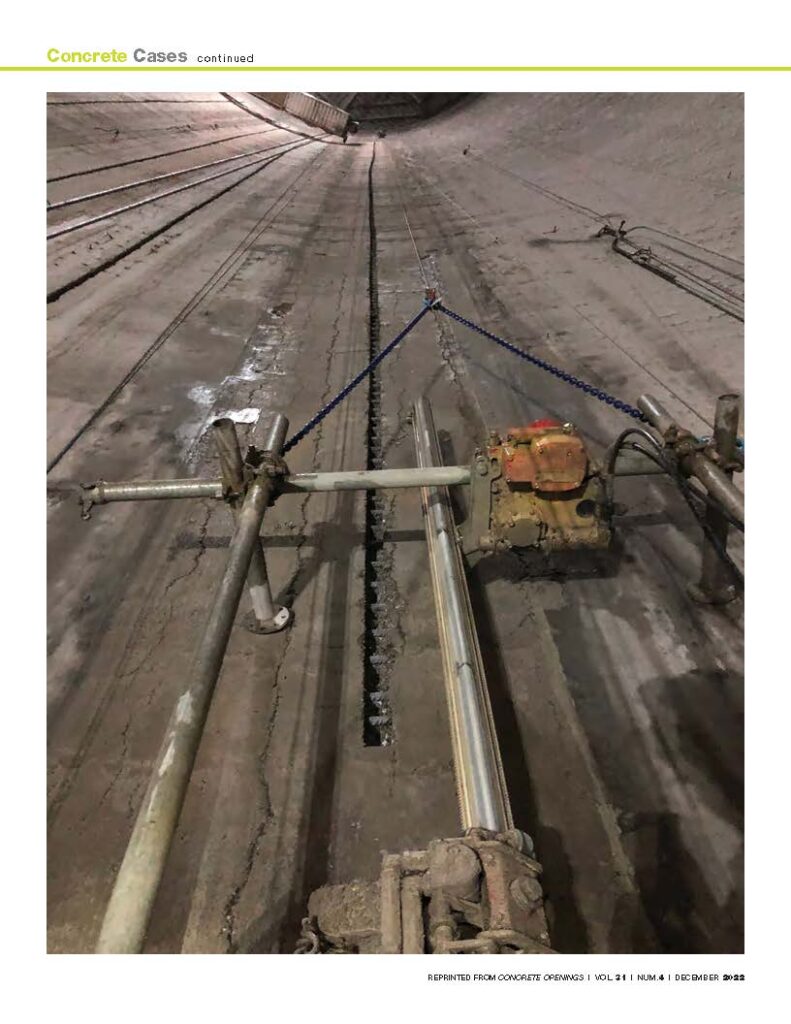

The Ergo is a compact hydrodemolition robot, with a climber that attaches to any standard scaffolding pipes and robotically moves along it, providing four times the power of a hand lance. Exerting 1,000 newtons of reaction force, the Ergo removes concrete or other material to a consistent preset depth. Its power, precision, speed, and easy mobility make it ideal when working on vertical vessels and it is a favorite of employees who appreciate its ease of use. Fixen currently has two Ergos – one used as the primary machine and the other as a back-up unit.

The cement plant’s maintenance shutdown had a deadline of four weeks, so it was critical to complete repairs quickly. Because of his previous experience working on the silo and knowing the scope of the project, the plant managers approached Rodriguez and asked if Fixen could reinforce and repair the silo.

Although Fixen was one of many contractors who competed for the job, they were the only company that proposed a robotic hydrodemolition method along with the use of hanging platforms to complete the work by the deadline.

“With traditional hand lancing for concrete repair, it would take a lot of time –up to 24 hours of non-stop work with a full crew of workers for four weeks or longer to complete this project. This is why the cement plant thought repairing the silo was an impossible task,” explained Rodriguez.

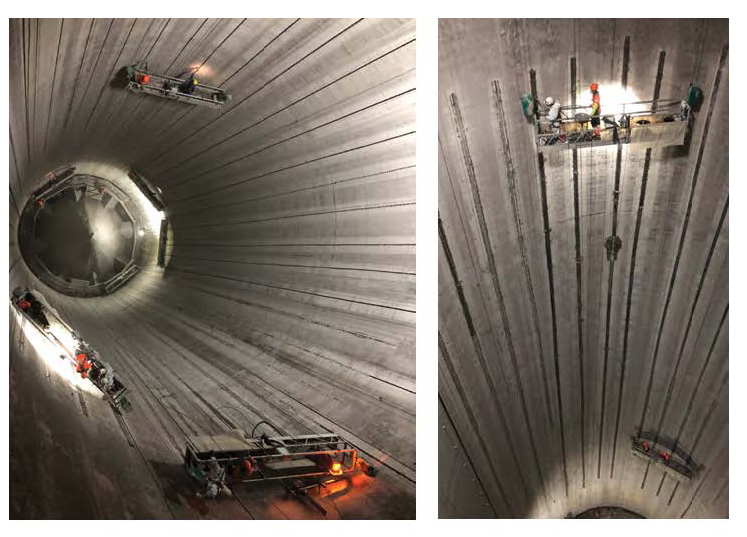

Fixen won the job by bringing an innovative solution that promised a repair that could be completed within four weeks. If Fixen failed to meet the deadline, they would have to cover the remaining cost of finishing the project. The pressure was on to complete a successful structural repair, but their team had confidence they could complete the repairs on time using the Ergo. The silo restoration job took place September 2021, two years after Rodriguez had worked on the first stages of the project with his former company. The silo had a total of 32 sections to repair, each 45m long. The Fixen team connected the Ergo to an electrical hoist to reach the areas of repair. Fixen first used the Ergo to cut and remove the silo’s deteriorating concrete, then installed stirrups to anchor the existing horizontal rebars and attach them to the concrete. The final step of the repair was to fill the open spaces with fluid mortar to complete the section. Thanks to the Ergo, the team achieved a production rate of one meter per minute, removing two 45m vertical sections of concrete each day.

“Hydrodemolition with the Ergo really exceeded our expectations and allowed us to raise our standard in terms of planning, accuracy and performance optimization,” said Rodriguez. “It took more time to move the electric hoist than to remove the concrete.”

Two crew members removed a total of 1,440m of concrete and finished the job with two days to spare. But as with any job, there were challenges. With the silo’s height of 100m, rather than using a traditional scaffolding system, the Fixen team decided to opt for a much safer motorized hanging platform to comfortably stand on and brought additional equipment up with them as they worked on the structure.

“When we founded our company, we wanted to be grounded on the philosophy of performing the best quality repair we can,” said Rodriguez, Chief Operating Officer of Fixen. “Although we have a small team, we are always excited to take on challenges – big or small – to expand our knowledge on our scope of work. We are open to trying new methods and equipment that can offer both power and simplicity to our projects in order to provide our customers with the best results possible.”

Additionally, the Fixen crew needed approximately 100m of constant water pressure to ensure a successful hydrodemolition repair. To achieve this, Fixen used a 2,500 bar Hammelman pump with a flow rate of 24L per minute.

The pump, situated on the ground for the duration of the project, incorporated a 120m long, 3,000 bar pressure, hose extending up the structure to the Ergo. The Ergo controller was placed on a hanging platform, following the Ergo climber on each 4m vertical section. The cement plant provided the water and discarded the blast water into a cistern on-site.

Equipped with practical knowledge of hydrodemolition and the Ergo, the Fixen team successfully repaired and completed a job that was deemed nearly impossible. “We are continuously surprised by the power and effectiveness of this machine when pursuing a variety of projects,” said Rodriguez. “We are proud to have given the cement plant a cost-effective and lasting solution to their operation.”

After a job well done, Fixen remains motivated to take on projects that allow them to use innovative equipment to solve the most challenging situations.

COMPANY PROFILE

Fixen Structural Services was established in 2019 to provide excellent structural repair and reinforcement for large structures, such as silos and bridges. The company, based in La Rinconada, Sevilla, Spain, works on projects across the globe. Fixen has a team of six, including two executive leaders, who are all skilled and trained in every service they provide.

RESOURCES

Contractor

Fixen Structural Services

CSDA Member

Aquajet

Contact for Story: Roger Simonsson

Tel: +46-383-246613

Email: roger.simonsson@aquajet.se

Website: www.aquajet.se

Methods Used: Robotic Demolition