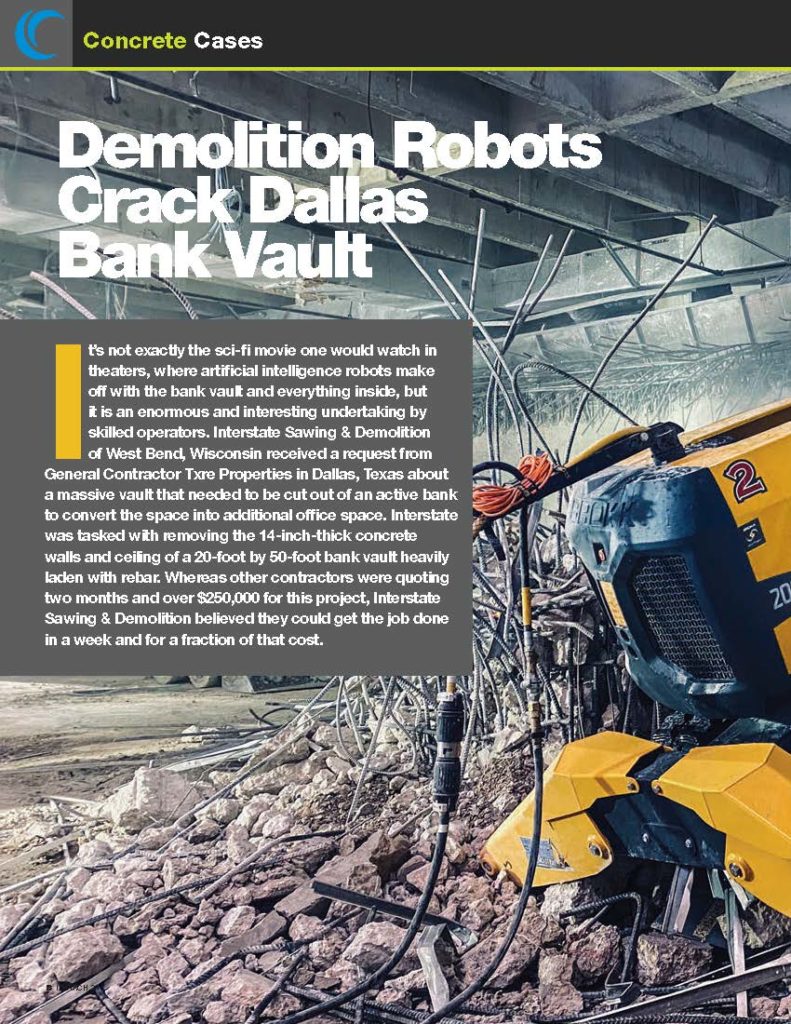

Demolition Robots Crack Dallas Bank Vault

It’s not exactly the sci-fi movie one would watch in theaters, where artificial intelligence robots make off with the bank vault and everything inside, but it is an enormous and interesting undertaking by skilled operators. Interstate Sawing & Demolition of West Bend, Wisconsin received a request from General Contractor Txre Properties in Dallas, Texas about a massive vault that needed to be cut out of an active bank to convert the space into additional office space. Interstate was tasked with removing the 14-inch-thick concrete walls and ceiling of a 20-foot by 50-foot bank vault heavily laden with rebar. Whereas other contractors were quoting two months and over $250,000 for this project, Interstate Sawing & Demolition believed they could get the job done in a week and for a fraction of that cost.

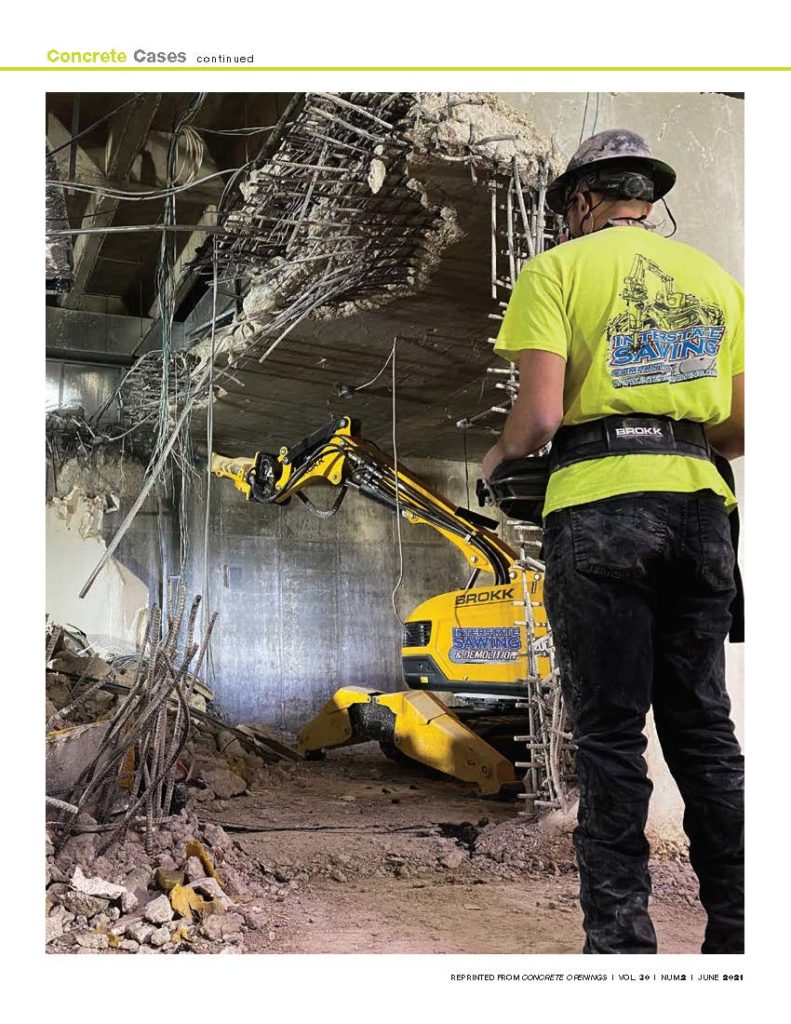

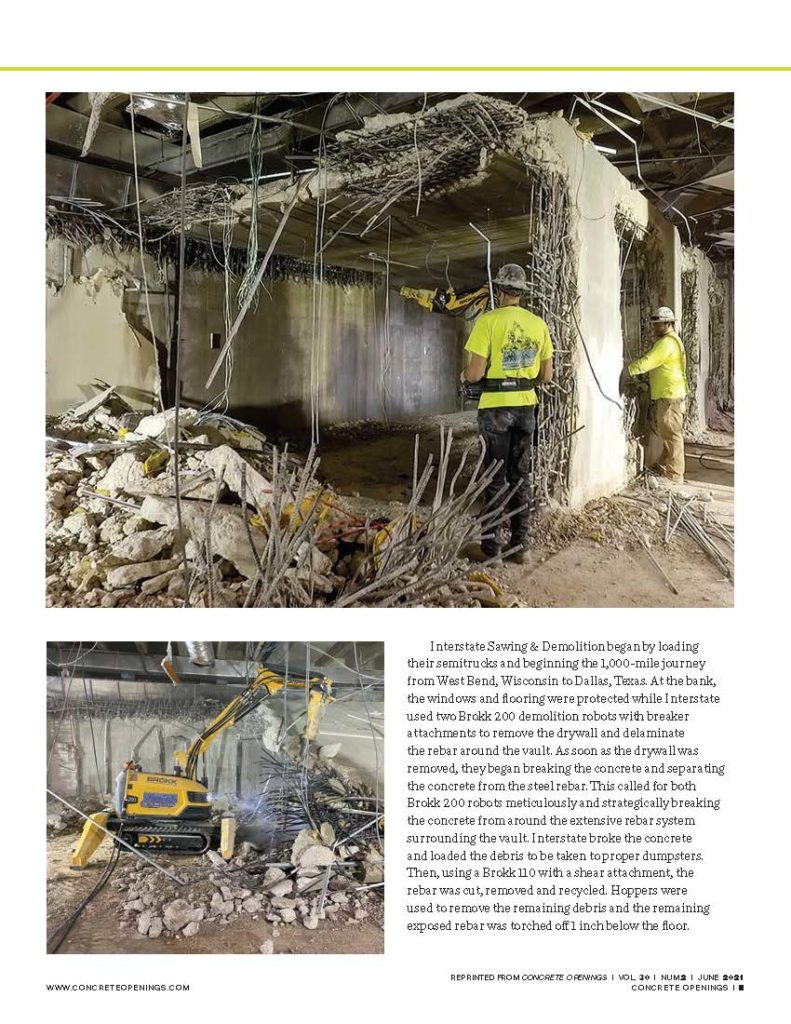

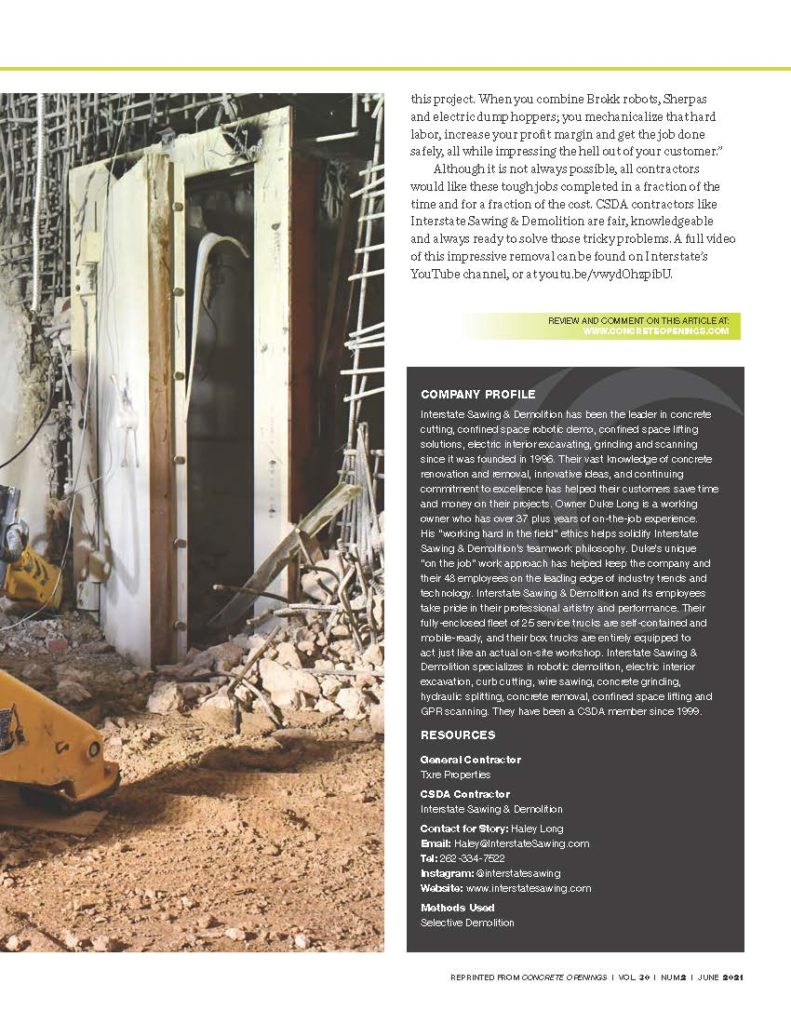

Interstate Sawing & Demolition began by loading their semitrucks and beginning the 1,000-mile journey from West Bend, Wisconsin to Dallas, Texas. At the bank, the windows and flooring were protected while Interstate used two Brokk 200 demolition robots with breaker attachments to remove the drywall and delaminate

the rebar around the vault. As soon as the drywall was removed, they began breaking the concrete and separating the concrete from the steel rebar. This called for both Brokk 200 robots meticulously and strategically breaking the concrete from around the extensive rebar system surrounding the vault. Interstate broke the concrete and loaded the debris to be taken to proper dumpsters. Then, using a Brokk 110 with a shear attachment, the rebar was cut, removed and recycled. Hoppers were used to remove the remaining debris and the remaining exposed rebar was torched off 1 inch below the floor.

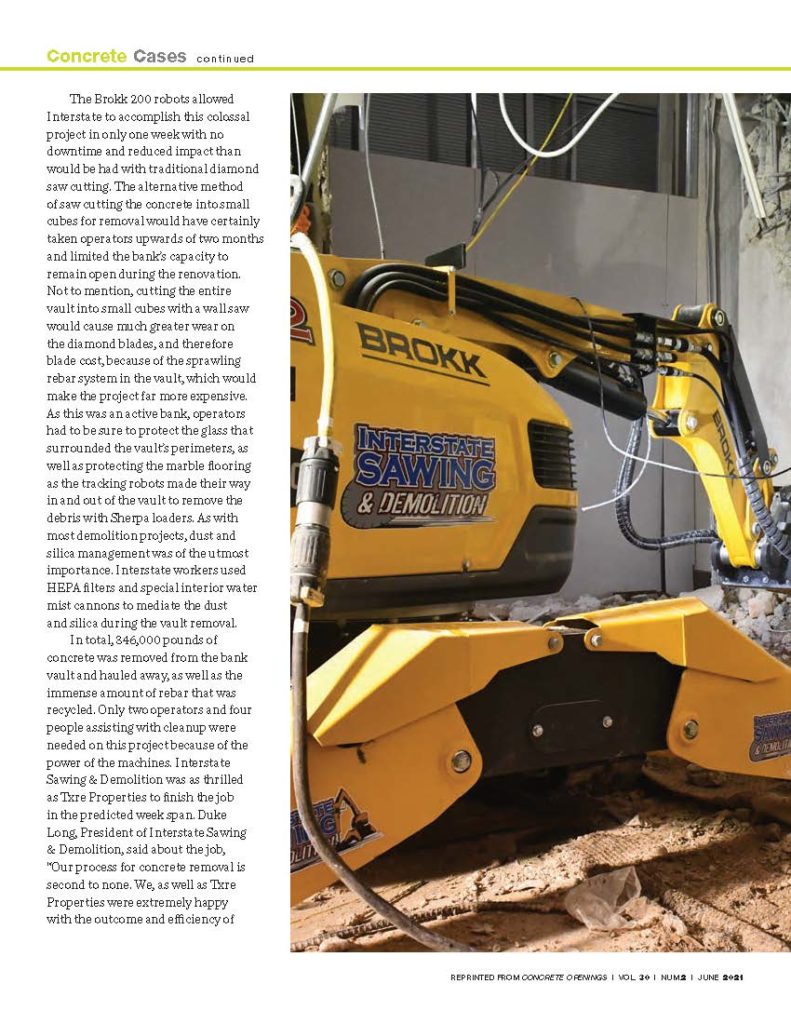

The Brokk 200 robots allowed Interstate to accomplish this colossal project in only one week with no downtime and reduced impact than would be had with traditional diamond saw cutting. The alternative method of saw cutting the concrete into small cubes for removal would have certainly taken operators upwards of two months and limited the bank’s capacity to remain open during the renovation. Not to mention, cutting the entire vault into small cubes with a wall saw would cause much greater wear on the diamond blades, and therefore blade cost, because of the sprawling rebar system in the vault, which would make the project far more expensive. As this was an active bank, operators had to be sure to protect the glass that surrounded the vault’s perimeters, as well as protecting the marble flooring as the tracking robots made their way in and out of the vault to remove the debris with Sherpa loaders. As with most demolition projects, dust and silica management was of the utmost importance. Interstate workers used HEPA filters and special interior water mist cannons to mediate the dust

and silica during the vault removal.

In total, 346,000 pounds of concrete was removed from the bank vault and hauled away, as well as the immense amount of rebar that was recycled. Only two operators and four people assisting with cleanup were needed on this project because of the power of the machines. Interstate Sawing & Demolition was as thrilled as Txre Properties to finish the job in the predicted week span. Duke Long, President of Interstate Sawing & Demolition, said about the job, “Our process for concrete removal is second to none. We, as well as Txre Properties were extremely happy with the outcome and efficiency of this project. When you combine Brokk robots, Sherpas and electric dump hoppers; you mechanicalize that hard labor, increase your profit margin and get the job done safely, all while impressing the hell out of your customer.”

Although it is not always possible, all contractors would like these tough jobs completed in a fraction of the time and for a fraction of the cost. CSDA contractors like Interstate Sawing & Demolition are fair, knowledgeable and always ready to solve those tricky problems. A full video of this impressive removal can be found on Interstate’s YouTube channel, or at youtu.be/vwydOhzpibU.

COMPANY PROFILE

Interstate Sawing & Demolition has been the leader in concrete cutting, confined space robotic demo, confined space lifting solutions, electric interior excavating, grinding and scanning since it was founded in 1996. Their vast knowledge of concrete renovation and removal, innovative ideas, and continuing commitment to excellence has helped their customers save time and money on their projects. Owner Duke Long is a working owner who has over 37 plus years of on-the-job experience. His “working hard in the field” ethics helps solidify Interstate Sawing & Demolition’s teamwork philosophy. Duke’s unique “on the job” work approach has helped keep the company and their 48 employees on the leading edge of industry trends and technology. Interstate Sawing & Demolition and its employees take pride in their professional artistry and performance. Their fully-enclosed fleet of 25 service trucks are self-contained and mobile-ready, and their box trucks are entirely equipped to act just like an actual on-site workshop. Interstate Sawing & Demolition specializes in robotic demolition, electric interior excavation, curb cutting, wire sawing, concrete grinding, hydraulic splitting, concrete removal, confined space lifting and GPR scanning. They have been a CSDA member since 1999.

RESOURCES

General Contractor: Txre Properties

CSDA Contractor: Interstate Sawing & Demolition

Contact for Story: Haley Long

Email: Haley@InterstateSawing.com

Tel: 262-334-7522

Instagram: @interstatesawing

Website: www.interstatesawing.com

Methods Used: Selective Demolition