SCANNING for SUCCESS on a $100M Wisconsin Casino Renovation

The Potawatomi Hotel and Casino in Milwaukee, Wisconsin, is currently undergoing a $100 million renovation to the third floor. The Potawatomi Casino is a chain of casinos operated by the Forest County Potawatomi Community; a Native American tribe based in Wisconsin who also operate several other casinos in other parts of the state.

The renovation will add new restaurants, gaming areas and entertainment experiences and covers a whopping 120,000-square-foot area. It includes the addition of 1,800 slot machine stations, new quick service food and beverage stations, a new bar, a gift shop and a collection of 4K televisions. Another major new feature will be the addition of an exclusive high-limit room, about which Potawatomi representatives state, “Guests will notice the energy from the new space the moment they walk in the door. The skywalk and entry area will feature modern décor, LED lighting, video walls and sound system throughout the third floor.”

Construction on the renovation project began in spring of 2023. Greenfire Management Services of Milwaukee, a wholly owned subsidiary of the Potawatomi Business Development Corporation, teamed with Gilbane Building Services as the general contractors on the project. CSDA member Interstate Sawing and Demolition was contracted and GPR operator, Donald Goebel, was requested to assist with the remodel of the 3rd floor renovation by using his ground penetrating radar (GPR) scanning expertise.

During the initial phase of the project, the first three days were dedicated to scanning large square footage areas ranging from approximately 150 to 800 square feet. Both the Screening Eagle GP8000 and the GP8800 GPR units were employed for this purpose. The need for scanning larger than normal areas was a result of the absence of an exact dimensional layout provided to the subcontractor and the need to stay on schedule.

Daily discussions were held to assess the progress of the scanning and address any challenges that emerged. These discussions served as a platform for the team to communicate any issues encountered during the scanning operations and promptly inform the general contractor. Open lines of communication ensured that any concerns were addressed immediately, minimizing potential delays and maintaining project momentum.

During the structural slab scanning process, it was discovered that a topping slab was present. A topping slab is a layer of concrete that is applied on top of an existing slab or structural surface, typically used to provide additional strength, protection or to level the surface. However, due to the active casino situated beneath, there was no access available below the slab to scan. As the topping slab was affecting scan results, it became clear it would be necessary to remove it to gain access to the underlying structural elements and accurately assess their condition.

This early effort in scanning and open communication laid a solid foundation for subsequent project phases, enabling the team to make informed decisions based on the data collected. The subcontractors removed 500 square feet of the scanned topping slab and Goebel was able to resume scanning for any substructures in the remaining slab.

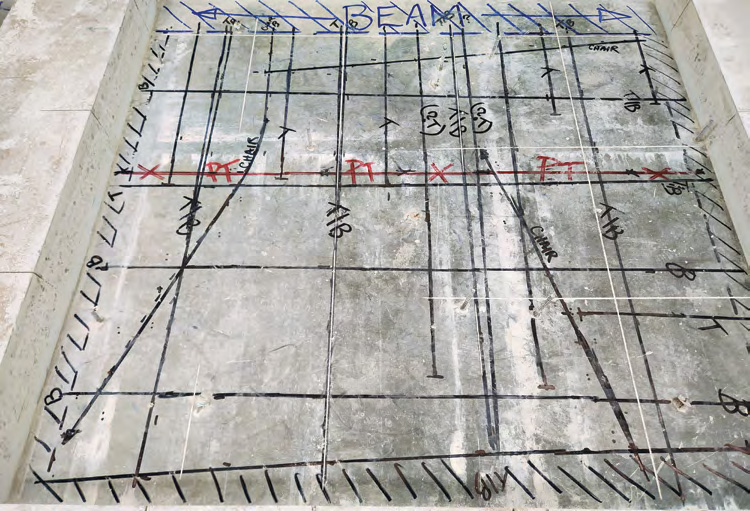

Goebel was able to determine that there were post-tensioned cables within the slab, based on the slab scan reflection patterns found. However, due to the thin nature of slab, the cables were considered temperature tendons as opposed to uniform tendons. Through his analysis of the scan results, he was able to identify the distinctive reflection patterns associated with the cables. These patterns are significant and requires specialized knowledge and experience, as it affects the approach and considerations for working with the post-tensioned structure.

As usual, ensuring safety precautions on a construction site was paramount. For this project, dirty floors and potential cut or scratch hazards were mitigated by implementing a clean-up routine to maintain a tidy work area and ensuring proper disposal of debris and waste materials. Personal protective equipment (PPE) including gloves and a dust protection mask were worn by Goebel and other contractors. With the removal of the topping slab, there were potential trip hazards and puncture hazards, so caution tape was placed around the areas where the slab was removed.

There were no incidents or issues during this project credited to the skillful scanning and identification of post-tension cabling. The accurate results reduced the risk of damaging any critical infrastructure during the construction phase. Overall, Goebel scanned 2,500 ft2 of slab for the casino, with over 400 core penetrations through the concrete slabs. The project is anticipated to be completed by fall of 2023.

Goebel’s expertise and willingness to take the necessary measures to obtain accurate data underscores his dedication to delivering reliable results. Through his efforts, potential risks or challenges associated with the structural slab were identified, allowing for proactive measures to be implemented to mitigate any potential issues. By addressing the presence of the topping slab and adapting the scanning approach accordingly, the project team demonstrated their commitment to thoroughness and their ability to adapt to unexpected circumstances. These efforts contributed to the overall success of the project, ensuring that the structural elements were evaluated accurately and paving the way for subsequent construction phases.

COMPANY PROFILE

Interstate Sawing and Demolition is headquartered in Madison, WI, with an additional branch location in Milwaukee, WI. They have 48 employees and a fleet of 25 service trucks, which are self-contained and mobile-ready. They specialize in robotic demolition, electric interior excavation, curb cutting, wire sawing, concrete grinding, hydraulic splitting, concrete removal, confined space lifting and GPR scanning. They have been a CSDA member since 1999.

RESOURCES

General Contractor

Gilbane/Greenfire management

CSDA Contractor

Interstate Sawing and Demolition

Contact: Donald Goebel

Email: donald@interstatesawing.com

Tel: 920-285-9113

Website: www.interstatesawing.com

Methods Used:

GPR Scanning