Two CSDA Contractors Work Together to Fill the Void

Two great contractors are always better than one. When a water main break caused a section of the floor of a building to buckle and crack from the immense pressure, the plumbing leak quickly became the least of the concern. The building owners feared the flooding water was forming a large diameter hole through the adjacent foundation wall and they were left searching for quick answers. General contractors were brought in to assess the suspected large-diameter hole that had formed in the concrete foundation wall on the east side of the building from the pressure coming from the northwest side of the building.

A contractor was hired to fix any structural and underground damage and spent the previous day cleaning up truckloads of sub-grade material that was forced above ground by the enormous water pressure. Upon seeing how much sub-grade material there was, a couple small diameter pilot holes were drilled into the floor to check for voiding. After confirming that voiding that taken place, it was of the utmost importance to discover the exact extent of the voided slab.

CSDA contractor Hard Rock Technologies specializes in Ground Penetrating Radar (GPR) and was called late in the afternoon to begin scanning the building the following day to perform a void detection scan using GPR. GPR is a non-destructive method for locating and visualizing under slab-voiding. Providing the extent of voiding in the area allows the contractor to develop a plan for repairs and to know what areas require repair and what areas were unphased by the water damage. Multiple forms of destructive methods could had been used; however, the contractor would had been going in blind with no knowledge of the exact areas that needed focus. GPR provides a game-plan of where the work and repairs need to be focused. For the size of the area, the functionality of the GPR equipment utilized was ideal.

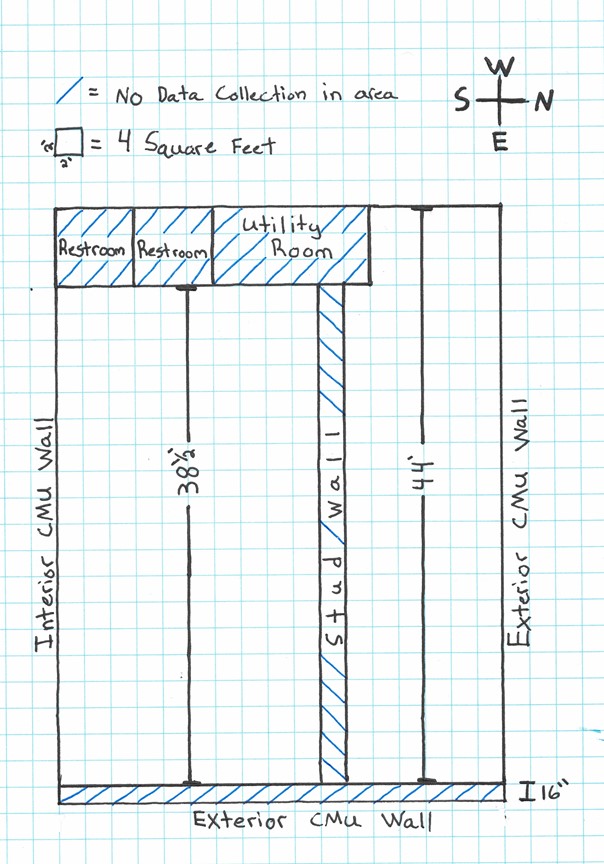

Upon arrival onsite, the technician realized that this was still very much a working facility with major clean-up still taking place. Taking place in a still active warehouse, the technician assisted in helping clear the areas of materials where data collection would take place. Once the area was cleared, the Hard Rock Technologies technician strategized the best route and direction to gather the most data possible. The technician began laying out framework which would allow the antenna to the technician began laying out the framework of a grid which would ensure the highest quality results. The technician used a Geophysical Survey Systems Inc. 1600 MHz Antenna attached to a Sir3000 Monitor to scan the affected area. The area was split into three sections due to existing stud and CMU walls. The three areas combined amounted to roughly 2125-square feet of scanned surface.

During data collection, the technician was able to confirm a large amount of voiding in the area. The area labeled “Area 2” in the office had a significant amount of voiding present.

Once all data collection was completed, the technician began taking measurements of fixed objects and distance of passes made from the starting point. These measurements would in turn be used in a sketch of the area(s) and provided to the customer for clarity. The collected data, including pictures and a copy of the sketches, were then sent to fellow CSDA member Echo GPR in Paola, Kansas. Echo GPR was able to run the data through a software program to provide a visual plan view of contrasting GPR signals similar to void signals. This plan view allowed for an easy to interpret visual for the client.

The biggest challenge in completing the job was working around a range of obstacles. Starting with the jobsite being an active warehouse under intense stress from clean-up and the damage that had been created. The technician had to work with and around the warehouse staff while they performed a salvage effort of materials. Existing plumbing also presented a major challenge. In the first area, the technician had to crawl under low-hanging plumbing in order to perform multiple necessary passes while at the same time not compromising data collection.

The main safety concern was the northwest corner of the building where the concrete was buckled and cracked. The technician took special care to not get anywhere near this area due to the fear that the slab was already far too comprised. There were also multiple forklifts moving boxes and various office materials in the warehouse at the same time data collection was taking place. The technician had to work with the warehouse staff to make sure that both parties were extremely aware of each other and taking turns in walking/driving through the area. Fortunately, the high-visibility vests aided in this process and kept operators safe.

The results were provided in a report form showing the contractor what areas needed to be addressed and what areas where left untouched by the water damage. The contractor was pleased with the results and knew who to call about a month later when another building was shown to have voiding. Ryan Hammer, the technician who performed the data collection and provided the customer with the subsequent report, said, “Its rewarding to see a project through from start to finish. A project, like most, where we are a key piece to the puzzle and timely accurate results are essential.”

Hammer also went on to say, “Being able to work hand-in hand with not only a fellow CSDA member, but a good friend, is equally satisfying. The connections made through CSDA lead to benefits for all companies involved; whether it’s being able to work together, call each other with interesting or challenging GPR scans or even just get another set of eyes on a raw data slice.” Hard Rock Technologies has a long-standing relationship with the contactor that hired them. They are well-known to work hard and provide accurate and reliable results to help on all their projects.

Company Profile

Hard Rock Technologies was founded in 2008 and proudly operates in the Chicagoland area. They specialize in ground penetrating radar for both concrete and utility applications, private utility locating and infrared inspection. They are a certified WBE contractor and have four total technicians, all of whom are CSDA certified GPR imaging technicians. They perform scans on up to 2,000 callouts per year with an accuracy rating of over 99.99%. Hard Rock Technologies has been a member of CSDA since 2011

Company Profile

Echo GPR–

RESOURCES

General Contractor

N/A

CSDA Contractor

Hard Rock Technologies

Contact for Story: Ryan Hammer

Email: Ryan@HRTScancom

Tel: 847-409-0554

CSDA Contractor

Echo GPR

Contact for Story: Mark DeSchepper

Email: Mark@EchoGPR.com

Methods Used

GPR Scanning