Bean There, Scanned That: GPR Scanning Chicago’s Popular Cloud Gate

When picturing Chicago, Illinois, the first image that might come to mind is the iconic stainless-steel Cloud Gate sculpture, also known colloquially as “The Bean.” Positioned in the heart of Millennium Park, Cloud Gate sits 66’ long by 33’ high and is made of 168 stainless steel plates seamlessly welded together, creating a remarkably reflective surface that was designed to mimic that of liquid mercury. The design, named Cloud Gate because of visitors’ ability to walk around as well as underneath it, while it reflects and distorts the city’s highly celebrated skyline, attracts around 5 million visitors annually.

While Chicagoans and visitors can enjoy the Riverwalk, Wrigley Field, deep dish pizza and towering skyscrapers, it would be wise to prepare for intense weather conditions. Chicago has well-known rainy cities like Seattle and Portland beat for highest annual rainfall. The excessive rainfall was affecting the drainage in Millennium Park, leading to standing water, which needed to be remediated before another hard-hitting Chicago winter made it much worse.

A local plumbing contractor was hired to reroute the irrigation around Cloud Gate. The path of the new plumbing was unknown, and core locations needed to be established where space in the ceiling existed. Zachary Goodspeed, from CSDA member company Hard Rock Technologies, used a Hilti PX 10Transpointer to precisely detect new core entry

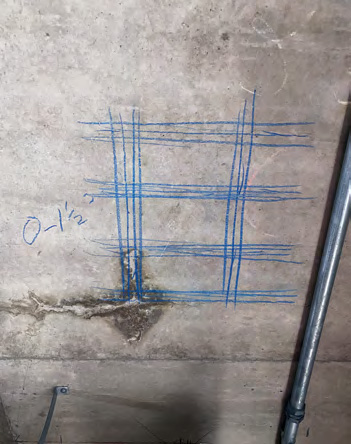

and exit points, as well as the distance between them. The PX 10 showed the slab to be approximately 18”–21” thick. Due to this thickness, better imaging would be achieved by scanning both the top and bottom side of the concrete slab. Goodspeed scanned 9 areas measuring 2’ x 2’ each using a GSSI SIR 3000 accompanied with a GSSI 2GHz Palm Antenna.

Goodspeed proceeded to locate all metal obstructions and potential conduits marking them directly on the concrete with crayon. “Having been to Cloud Gate several times throughout my life, I never imagined I would get to use my professional expertise to keep something so iconic functioning for future generations. I couldn’t resist taking a photo,” said Goodspeed about the “selfie” photo of him scanning in front of “The Bean” sculpture.

Hard Rock Technologies is synonymous with GPR scanning and multiple other non-destructive testing methods not only in Chicago, but throughout the Midwest. Their 5 CSDA Certified GPR Technicians bring the skills and devotion this industry deserves. Hard Rock Technologies credits almost 15 years of excellent work and their strong reputation as to why they were chosen to provide the trusted results to such an iconic attraction.

Ryan Hammer, Vice President of Hard Rock Technologies, said about Certified Technician Zachary Goodspeed’s performance, “Zachary’s pride and dedication to his craft is palpable, his approach is methodical, and his results are precise. Customers request him by name and sing his praises often. Zachary is a valued member of the Hard Rock Technologies family and I have had the pleasure of working beside him for the last 5 years”

COMPANY PROFILE

Hard Rock Technologies has been serving the Midwest for nearly 15 years. They provide ground penetrating radar, utility locating, infrared imaging, and other state of the art technologies designed to help find the best solutions for any job site with accuracy, integrity, efficiency and safety. They have been a CSDA member since 2011.

RESOURCES

Contractor

Hard Rock Technologies

Contact for Story: Ryan Hammer

Email: ryan@hrtscan.com

Tel: 847-275-4007

Website: www.hardrocktechnologies.com

Methods used

GPR Scanning