The Geisel House Project: Holes Incorporated’s Role in Preserving History

Situated about 70 miles northwest of Houston, Texas is a small town with a big history. Navasota, Texas was up-and-coming as the Civil War began, which is when R. H. Giesel and his wife, Fannie, chose to construct two three-story buildings to serve as a hotel and restaurant. Located near the Houston & Texas Central Railroad Depot, this stone building, originally built in 1860 with a two-story frame porch on the front, beckons to the architecture of the mid-1800s. The town of Navasota suffered a population decline when, in 1862, disgruntled confederate soldiers set fire to a warehouse. The fire damaged so many surrounding buildings, many citizens fled. By the late 1860s, the town was struck with Yellow Fever, and by the turn of the century, was completely lawless and ungovernable. In a current effort toward developing the downtown area to bolster tourism, the Giesel House was given a chance at a new life and a total revamp.

General contractor, B&A Commercial Contractors was hired by owner of the hotel, P.A. Smith Hote, to renovate and connect the two historical buildings, which had acted as the restaurant and hotel, to turn the property into a single boutique hotel. This effort hoped to enliven the downtown area and bring people back to Navasota. All of the original woodwork, wood flooring and concrete walls were to be preserved for the boutique hotel. The contractor also wanted the main wooden beams in both buildings to be carefully preserved during construction. However, new electrical, plumbing and openings needed to be created to connect the two buildings – and that is when CSDA contractor Holes Incorporated was hired.

Holes was initially contracted to wall saw two individual 3-foot by 8-foot openings needed to connect the two buildings. One opening was located on the second floor and the other was on the third floor. B&A Commercial did not know the thickness of the combined walls, so a core drill operator was sent from Holes to drill into the wall and make that determination. Using a Shibuya core drill, it was discovered that the two building walls were a massive 44 inches thick. Since the contractors needed to preserve so much of this building, overcuts were simply not an option. With this in mind, the possibility of wall sawing these openings was ruled out, and wire sawing was chosen as the method of removal.

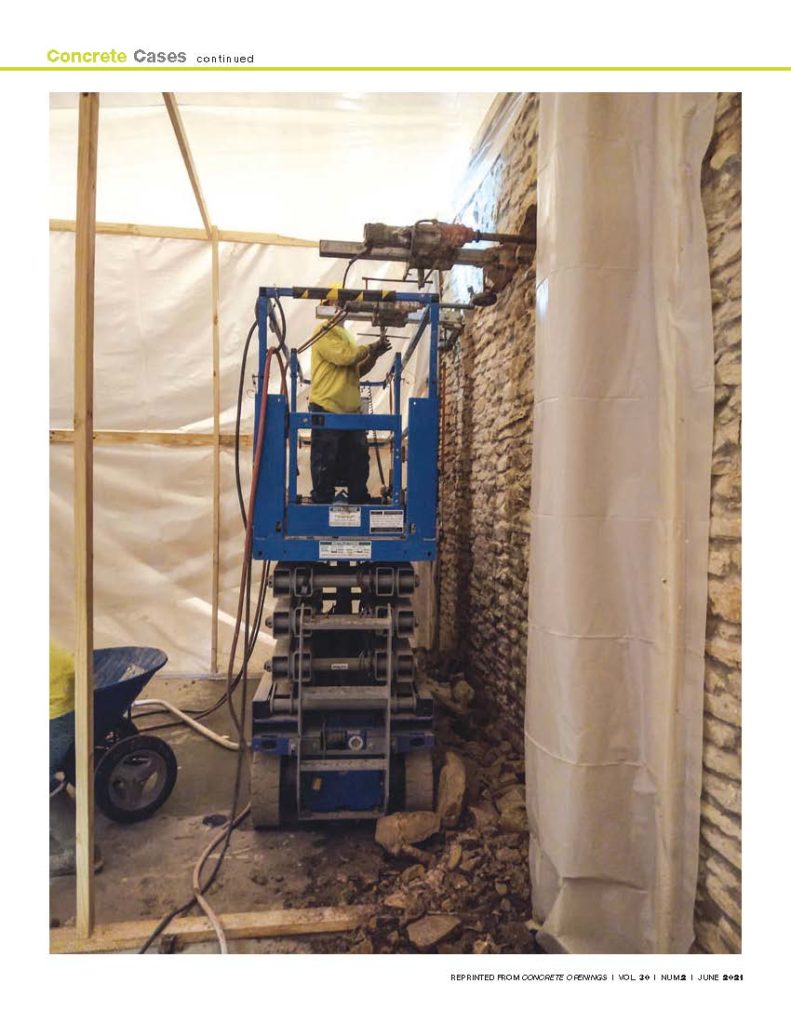

To prepare for the sawing, Holes operators erected a plastic enclosure around the work areas on both sides of the walls in both buildings to prevent damage to existing surfaces, and protective flooring was installed inside and outside of the enclosure. Spray foam was used inside of the wall to avoid water and slurry from seeping through to lower levels. The walls were made of sandstone, which forced operators to through-bolt all equipment to the wall, as normal anchoring systems would not work.

During the inspection of the layout, the Holes Lead Operator and Field Safety Supervisor, whom Holes had onsite throughout the duration of the project, noticed that the contractor’s layout was off by 6 inches because the two buildings were slightly offset. The realization that one building was staggered 6 inches in front of the other caused a bit of panic among everyone, but was quickly and fortunately detected prior to cutting.

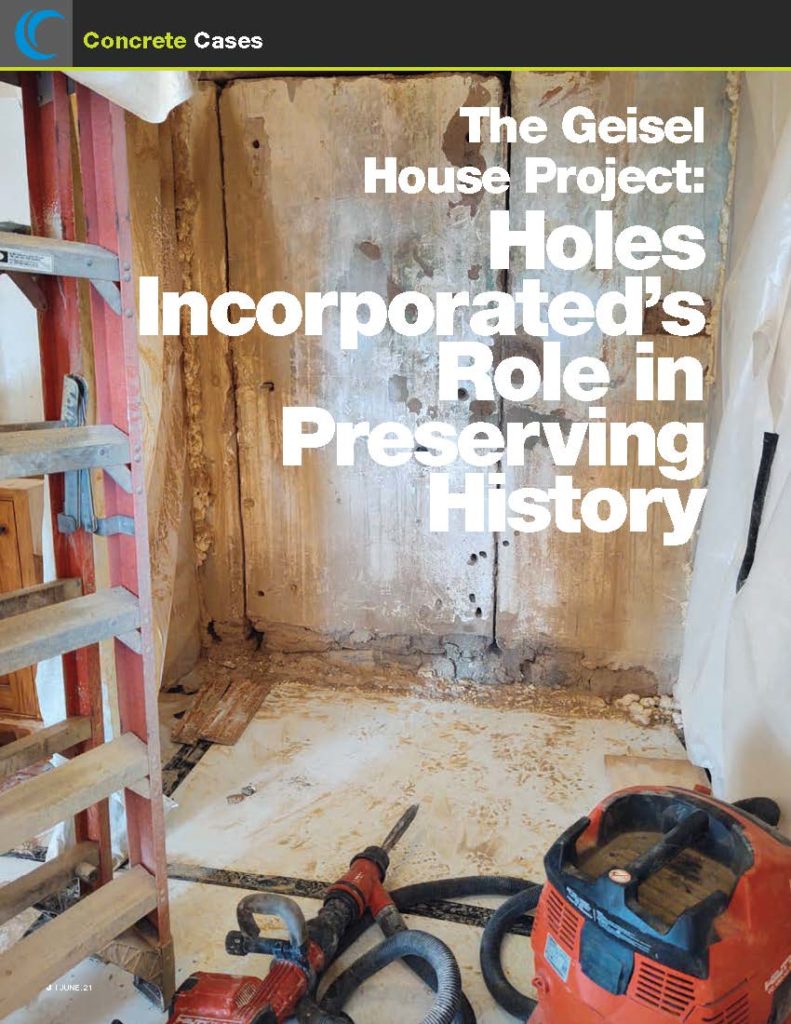

The GC, with assistance from Holes operators, installed two lintels prior to saw cutting the door openings. Without the lintels, there was a fear of the sandstone openings crumbling without support. Holes operators used a Husqvarna Hi-cycle chainsaw to saw cut both buildings on either side of the wall to create the lintel opening. Utilizing diamond blades and chains allowed operators to cut the perfectly straight and level lines needed while avoiding the excessive vibration that could risk structural damage to the historical building. The Husqvarna CS2512 wire saw was used to complete the door openings, the wall was then demolished using a small Hilti demo-hammer with a dustless system and dry vacuum. The wall was already falling apart, so the jackhammer assisted in breaking it up into manageable pieces for removal by the Holes team. The pieces were removed from the building with wheelbarrows, using an antique historical freight elevator.

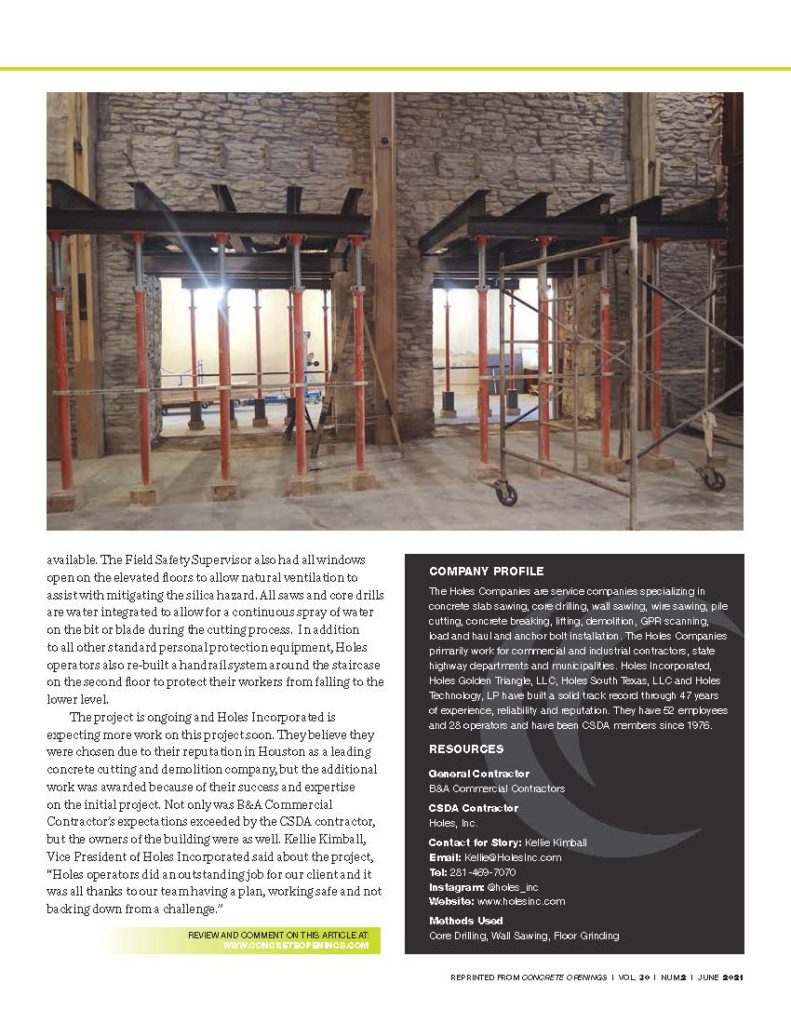

Upon successful completion of the two individual openings, the GC awarded Holes additional work and requested they cut two additional 8-foot-wide by 8-foot-tall openings. These openings, again, were to connect the buildings to create walkways between the two buildings on the first floor. Because the structural integrity of the sandstone walls was a concern, prior to cutting the openings, they had to drill ten 12-inch by 44-inch cores to install five inch-wide I-beams made of structural steel. Once the beams were in place, the cutting could begin!

Despite the challenges with communication between two buildings with two different teams working on multiple different phases of a project, the Holes team was able to complete the wire sawing of four openings totaling 108 feet long by 44 inches deep. In addition, various sized core drilled holes ranging from one inch to four inches were completed and successfully drilled to run wire through both buildings, despite operating this equipment on the antiquated structure with priceless chandeliers hanging beneath them, as well as new drywall. At this phase in the project, much of the construction by the GC was completed and Holes operators had to work carefully around the finished work.

Coordinating and communicating with both teams in both buildings posed a challenge for everyone onsite. With renovations, slurry control, sawing and demolition all happening at once, any incident required both teams to stop working and investigate. Good communication was absolutely key to the success of this job, as it is to so many. Respirable crystalline silica was a concern due to the enclosed nature of the work areas, so Holes operators wore respiratory protection during cutting when working inside the enclosure and dustless equipment was used with dry vacs when available. The Field Safety Supervisor also had all windows open on the elevated floors to allow natural ventilation to assist with mitigating the silica hazard. All saws and core drills are water integrated to allow for a continuous spray of water on the bit or blade during the cutting process. In addition to all other standard personal protection equipment, Holes operators also re-built a handrail system around the staircase on the second floor to protect their workers from falling to the lower level.

The project is ongoing and Holes Incorporated is expecting more work on this project soon. They believe they were chosen due to their reputation in Houston as a leading concrete cutting and demolition company, but the additional work was awarded because of their success and expertise on the initial project. Not only was B&A Commercial Contractor’s expectations exceeded by the CSDA contractor, but the owners of the building were as well. Kellie Kimball, Vice President of Holes Incorporated said about the project, “Holes operators did an outstanding job for our client and it was all thanks to our team having a plan, working safe and not backing down from a challenge.”

COMPANY PROFILE

The Holes Companies are service companies specializing in concrete slab sawing, core drilling, wall sawing, wire sawing, pile cutting, concrete breaking, lifting, demolition, GPR scanning, load and haul and anchor bolt installation. The Holes Companies primarily work for commercial and industrial contractors, state highway departments and municipalities. Holes Incorporated, Holes Golden Triangle, LLC, Holes South Texas, LLC and Holes Technology, LP have built a solid track record through 47 years of experience, reliability and reputation. They have 52 employees and 28 operators and have been CSDA members since 1976.

RESOURCES

General Contractor: B&A Commercial Contractors

CSDA Contractor: Holes, Inc.

Contact for Story: Kellie Kimball

Email: Kellie@HolesInc.com

Tel: 281-469-7070

Instagram: @holes_inc

Website: www.holesinc.com

Methods Used: Core Drilling, Wall Sawing, Floor Grinding